Introduction to Freezer Pistons

In the realm of commercial refrigeration, efficiency and reliability are paramount. One of the critical components contributing to these attributes is the freezer piston. These pistons play a vital role in ensuring the optimal performance of refrigeration systems. MINGYU, a leading Aluminum Forge manufacturer, has been at the forefront of developing advanced freezer pistons that significantly enhance cooling efficiency.

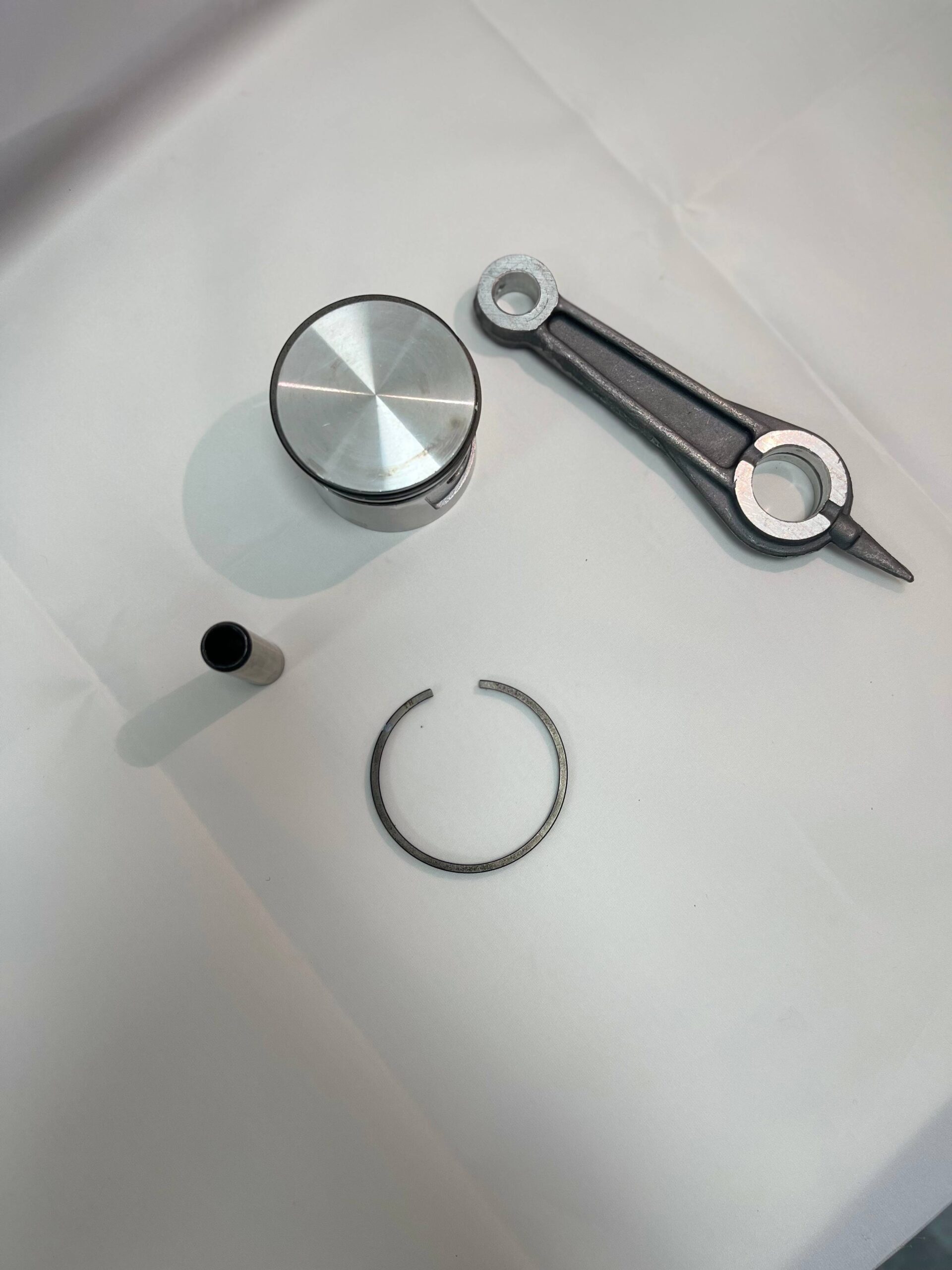

The Role of Freezer Pistons in Refrigeration Systems

Freezer pistons are integral to the operation of compressors within refrigeration systems. They are responsible for compressing the refrigerant gas, which is essential for the cooling cycle. The efficiency of these pistons directly impacts the overall performance of the refrigeration unit, influencing both energy consumption and cooling capacity.

The piston’s movement within the cylinder compresses the refrigerant, increasing its pressure and temperature. This process is crucial as it allows the refrigerant to release heat when it reaches the condenser, ultimately leading to the cooling effect in the evaporator.

Advancements by MINGYU in Aluminum Forging

MINGYU has leveraged its expertise in aluminum forging to produce freezer pistons that are not only durable but also lightweight. The use of aluminum in piston manufacturing offers several advantages, including improved thermal conductivity and resistance to corrosion. These properties are essential for maintaining the pistons’ integrity and performance over time.

The forging process employed by MINGYU ensures that the aluminum pistons have a uniform grain structure, enhancing their strength and reliability. This process also allows for the production of pistons with complex geometries, which can be tailored to meet the specific needs of different refrigeration systems.

Benefits of Using Aluminum Freezer Pistons

One of the primary benefits of aluminum freezer pistons is their ability to improve the overall energy efficiency of refrigeration systems. Aluminum’s lightweight nature reduces the mechanical load on the compressor, leading to lower energy consumption and, consequently, reduced operational costs.

Additionally, aluminum pistons offer excellent thermal conductivity, which helps in the rapid dissipation of heat generated during the compression process. This characteristic is crucial for maintaining the system’s efficiency and preventing overheating, which can lead to system failures.

Impact on Cooling Efficiency

The enhanced cooling efficiency provided by aluminum freezer pistons translates into faster cooling cycles and more consistent temperature maintenance within the refrigeration unit. This consistency is critical for commercial applications where precise temperature control is necessary to preserve perishable goods.

Moreover, the improved efficiency contributes to a reduction in the refrigeration system’s carbon footprint. By consuming less energy, these systems help in minimizing environmental impact, aligning with global efforts towards sustainability.

Durability and Longevity

The durability of MINGYU’s aluminum freezer pistons is another significant advantage. The robust nature of forged aluminum ensures that the pistons can withstand the high pressures and temperatures encountered during operation without deforming or wearing out prematurely.

This durability translates into a longer lifespan for the pistons and, by extension, the refrigeration system. Businesses benefit from reduced maintenance costs and fewer interruptions due to system failures, enhancing overall productivity and profitability.

Customization and Versatility

MINGYU’s ability to customize freezer pistons to meet specific requirements is a testament to their versatility. Different refrigeration systems may require pistons with varying dimensions, shapes, and performance characteristics. MINGYU’s advanced forging techniques allow for the creation of pistons that precisely match these specifications.

This level of customization ensures that each refrigeration system operates at its peak efficiency, regardless of the application or environmental conditions. The adaptability of aluminum pistons makes them suitable for a wide range of commercial refrigeration systems, from small-scale units to large industrial installations.

Conclusion

In conclusion, freezer pistons are a critical component in enhancing the cooling efficiency of commercial refrigeration systems. MINGYU’s advancements in aluminum forging have resulted in pistons that offer superior performance, durability, and energy efficiency. By choosing MINGYU’s aluminum freezer pistons, businesses can achieve significant cost savings, improved reliability, and a reduced environmental footprint.

As the demand for efficient and sustainable refrigeration solutions continues to grow, the role of advanced components like aluminum freezer pistons will become increasingly important. MINGYU remains committed to innovation and excellence in manufacturing, ensuring that their products meet the evolving needs of the commercial refrigeration industry.