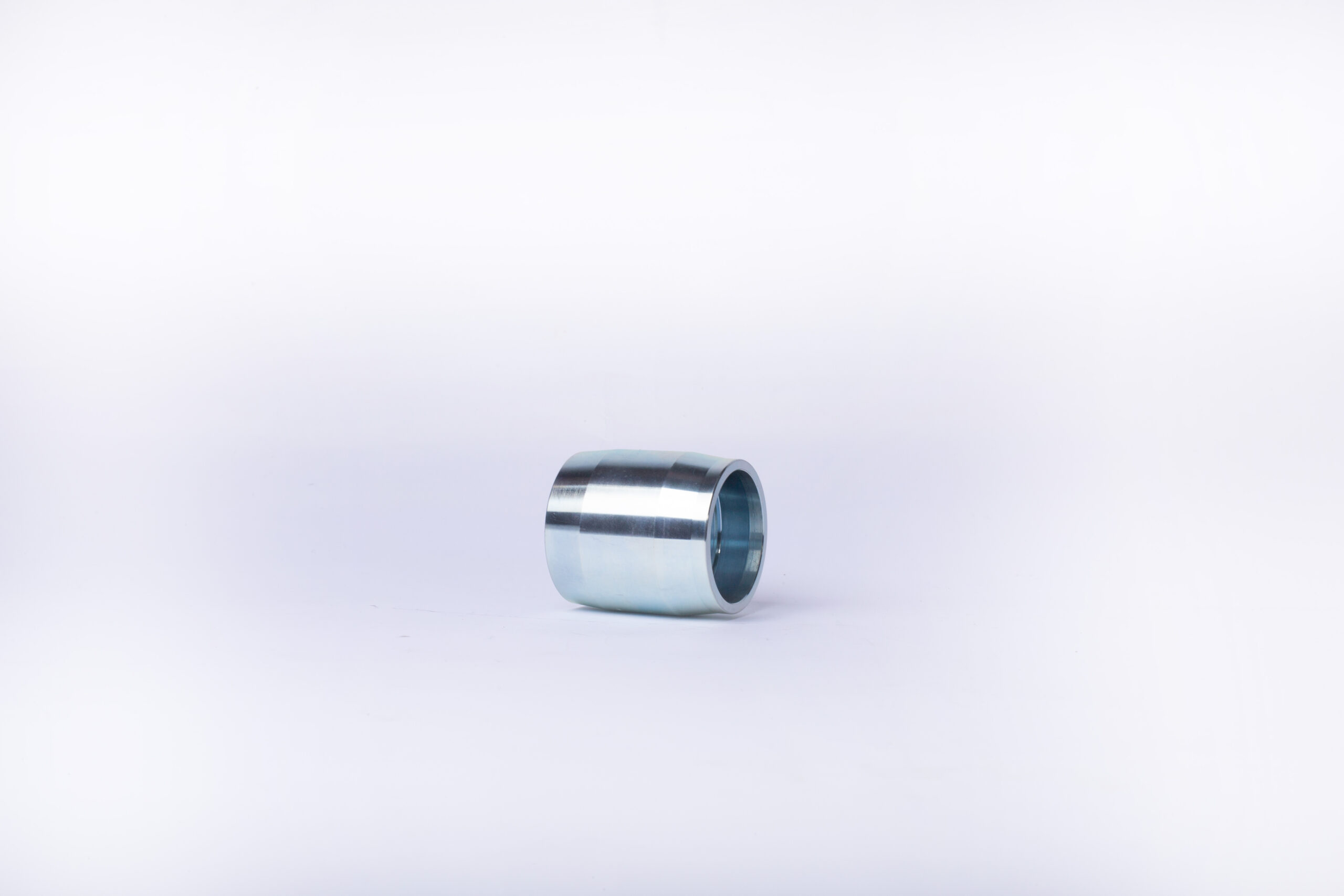

Product Name: Aluminum Forging

Product Type: Metal Forging

Material: Aluminum

Shape: Customized

Surface Treatment: Anodizing, Powder Coating, Spray Painting, Polishing

Production Process: Die Casting, Press Forging

Advantages:

1. High strength-to-weight ratio

2. Superior mechanical properties

3. Enhanced resistance to fatigue and wear

4. Tight dimensional tolerances

5. Cost-effective production

| Color | Silver |

|---|---|

| Material | Aluminum |

| MOQ | 1 Pcs |

| Sample | Available |

| Place of Origin | China |

Product Details

MINGYU Tech is a globally renowned aluminum extrusion cnc router manufacturer. Our company specializes in high-volume production of extruded parts for automotive, aerospace and other industrial applications. We have a fully integrated manufacturing process from design and engineering to finishing and packaging for efficient and cost-effective production. With its focus on innovation and quality control, MINGYU Tech has become the preferred supplier to many top companies around the world.

One of the key benefits of aluminum extrusion cnc router is its lightweight yet durable nature. The aluminum alloys used in this process have excellent strength-to-weight ratios, making them ideal for applications that require strength and stability without adding excess weight. This makes aluminum extrusion cnc router a popular choice for aviation, automotive, and construction industries.

Furthermore, aluminum extrusion cnc router have excellent corrosion resistance, making them suitable for use in outdoor and high-moisture environments. The material is also highly malleable, allowing for a variety of surface finishes to be applied, including anodizing, powder coating, and polishing. This makes aluminum extrusion cnc router highly versatile and customizable for different aesthetic and functional requirements.

| OEM/ODM | Yes |

| Length | Customised Length |

| shape | customized |

| Material | 6463 6063 Aluminum Alloys |

| Colour | Customised colour |

| MOQ | 150 Kilograms |

| Fabrication | Machining, CNC, sawing, milling, punching, lathing, tapping, chamfering, laser, cold drawing |

| Type | windor frame, Home decoration profiles,furniture products,furniture handle. |

| Certificate | For SGS, ISO9001 2015, RoHS |

| Surface Processing | Anodize, Polish, Brush, Coating |

aluminum extrusion cnc router FAQs Guide.

In this guide, we will provide you with all the information you need to know about our top-quality aluminum extrusion cnc router and how they can benefit you and your projects. With extensive experience in the industry, our products are trusted by professionals and DIY enthusiasts alike. From industrial applications to home improvement projects, our aluminum extrusion cnc router offer durability, versatility, and customization options to meet all your needs. Read on to discover more about our aluminum extrusion cnc router products and why they should be your top choice.

1.What are the common surface finishes for aluminum extrusion cnc router?

We should perform well in market competition, and the prices of aluminum extrusion cnc router products have a great competitive advantage.

1. Anodizing

2. Powder Coating

3. Brushing

4. Polishing

5. Sandblasting

6. Laser Engraving

7. Chemical Film

8. Electroplating

2.What are the factors that determine the strength of an extruded product?

Our products & services cover a wide range of areas and meet the needs of different fields.

1. Alloy composition: The alloy composition of the material used to make the extruded product will affect its strength. Different alloys have different properties, and some are stronger than others.

2. Extrusion temperature: The temperature at which the material is extruded will affect the strength of the product. Higher temperatures can cause the material to become more malleable, which can lead to a weaker product.

3. Extrusion speed: The speed at which the material is extruded will also affect the strength of the product. Faster speeds can cause the material to become more malleable, which can lead to a weaker product.

4. Die design: The design of the die used to extrude the material will also affect the strength of the product. Different die designs can cause the material to be extruded in different ways, which can lead to different strengths.

5. Cooling rate: The rate at which the material is cooled after extrusion will also affect the strength of the product. Faster cooling rates can cause the material to become more brittle, which can lead to a weaker product.

3.Can aluminum extrusion cnc router be used in corrosive environments?

We pay attention to user experience and product quality, and provide the best product quality and lowest production cost for cooperative customers.

Yes, aluminum extrusion can be used in corrosive environments. Aluminum is a corrosion-resistant material, and when used in extrusion, it can be further protected with a variety of coatings and finishes. These coatings and finishes can help protect the aluminum from corrosion and other environmental factors.

4.Can aluminum extrusion cnc router be used for medical devices?

Yes, aluminum extrusion can be used for medical devices. Aluminum extrusion is a process that is used to create complex shapes and components from aluminum. It is often used in the medical device industry to create components such as housings, frames, and other parts. Aluminum extrusion is a cost-effective and efficient way to create components for medical devices.

5.How does the design of a product impact the extrusion process?

We should have a stable supply chain and logistics capabilities, and provide customers with high -quality, low -priced aluminum extrusion cnc router products.

The design of a product can have a significant impact on the extrusion process. The shape, size, and complexity of the product will determine the type of extrusion process that is used, as well as the type of tooling and dies that are required. Additionally, the design of the product will determine the amount of material that is needed, the speed of the process, and the amount of time it takes to complete the extrusion process.

6.What are the advantages of using aluminum extrusion cnc router over other manufacturing processes?

Our mission is to provide customers with the best solutions for aluminum extrusion cnc router.

1. Cost-effectiveness: Aluminum extrusion is a cost-effective process that can produce complex shapes with minimal waste.

2. Versatility: Aluminum extrusion can be used to create a wide variety of shapes and sizes, making it a versatile manufacturing process.

3. Strength: Aluminum extrusion is a strong and durable process that can produce parts with high strength-to-weight ratios.

4. Design Flexibility: Aluminum extrusion allows for a wide range of design possibilities, allowing for complex shapes and intricate details.

5. Speed: Aluminum extrusion is a fast process that can produce parts quickly and efficiently.

6. Recyclability: Aluminum is a recyclable material, making aluminum extrusion an environmentally friendly process.

7.What industries commonly use aluminum extrusion cnc router?

We operate our aluminum extrusion cnc router business with integrity and honesty.

1. Automotive

2. Aerospace

3. Construction

4. Electronics

5. Furniture

6. Lighting

7. Medical

8. Marine

9. Signage

10. Telecommunications

8.What is the difference between standard and custom aluminum extrusion cnc routers?

We have been working hard to improve service quality and meet customer needs.

Standard aluminum extrusions are pre-made shapes and sizes that are available for purchase from a manufacturer. These extrusions are typically used for general purpose applications and are available in a variety of shapes and sizes. Custom aluminum extrusions are made to order and are designed to meet specific customer requirements. These extrusions are typically used for more specialized applications and are not available in standard sizes.

9.What advancements have been made in the aluminum extrusion cnc router process in recent years?

We have advanced production equipment and technology to meet the needs of customers, and can provide customers with high quality, low priced aluminum extrusion cnc router products.

1. Automation: Automation has been a major advancement in the aluminum extrusion process in recent years. Automated systems can reduce labor costs, improve product quality, and increase production efficiency.

2. Improved Die Design: Advances in die design have allowed for more complex shapes to be extruded with greater accuracy and precision.

3. Improved Alloy Selection: New alloys have been developed that are better suited for extrusion, allowing for improved strength and durability.

4. Improved Cooling Systems: Improved cooling systems have been developed that allow for faster cooling times and improved product quality.

5. Improved Quality Control: Quality control systems have been developed that allow for better monitoring of the extrusion process and improved product quality.

10.How does aluminum extrusion cnc router work?

We have a wide range of aluminum extrusion cnc router customer groups and establishes long -term cooperative relationships with partners. The countries we provide services include $keyworrd{国家变量}.

Aluminum extrusion is a process in which aluminum is forced through a die of the desired cross-sectional profile. The aluminum is heated to a temperature of around 500°F (260°C) and then forced through the die by a ram. As the aluminum passes through the die, it takes on the shape of the die. The extruded aluminum is then cooled and cut to the desired length. The extruded aluminum can then be used for a variety of applications, such as window frames, door frames, and structural components.

11.What is the difference between hot and cold extrusion?

aluminum extrusion cnc router is not a product only, but also can help you comes to money-making.

Hot extrusion is a process in which a metal is heated to a temperature above its recrystallization temperature and then forced through a die to form a desired shape. Cold extrusion is a process in which a metal is forced through a die at room temperature or slightly above. Cold extrusion is typically used for softer metals such as aluminum, copper, and brass, while hot extrusion is used for harder metals such as steel and titanium. Hot extrusion is more expensive and time consuming than cold extrusion, but it produces a stronger and more precise product.

12.What types of products can be made with aluminum extrusion cnc router?

We have a professional team that is committed to the innovation and development of aluminum extrusion cnc router.

Aluminum extrusion can be used to create a wide variety of products, including window and door frames, furniture, shelving, automotive parts, electronics, and medical equipment. It can also be used to create custom shapes and sizes for a variety of applications.

13.How does the use of aluminum extrusion cnc router impact the recyclability of a product?

We have the leading technology and innovation capabilities, and attach importance to employee training and development, and provide promotion opportunities.

The use of aluminum extrusion can have a positive impact on the recyclability of a product. Aluminum is a highly recyclable material, and extruded aluminum products can be recycled with minimal energy and cost. The extrusion process also helps to reduce the amount of scrap material generated, which can further reduce the environmental impact of the product. Additionally, aluminum extrusion can be used to create products with a longer lifespan, which can reduce the need for replacement and further reduce the environmental impact of the product.

14.Are there any limitations to the design possibilities with aluminum extrusion cnc router?

Our aluminum extrusion cnc router products have competitive and differentiated advantages, and actively promote digital transformation and innovation.

Yes, there are some limitations to the design possibilities with aluminum extrusion. The most common limitation is the size of the extrusion profile, as the profile must fit within the available space. Additionally, the shape of the profile may limit the design possibilities, as certain shapes may not be suitable for certain applications. Finally, the strength of the aluminum alloy used in the extrusion may limit the design possibilities, as certain applications may require a stronger alloy.

15.Can aluminum extruded products be welded?

We focus on innovation and continuous improvement to maintain a competitive advantage.

Yes, aluminum extruded products can be welded. However, the welding process must be done carefully to ensure that the welded joint is strong and free of defects.

Tag:aluminum extrusions frames,aluminum curtain wall extrusions,aluminum extrusion boss,aluminum extrusion 3d printer

Product Inquiry

We will respond within 12 hours, please pay attention to the email “@163.com” or “@alumforge.com”.

Also, you can go to the Contact Page, which provides a more detailed form, if you have more inquiries for products or would like to obtain OEM service.

Our sales experts will respond within 24 hours, please pay attention to the email with the suffix “@163.com”.