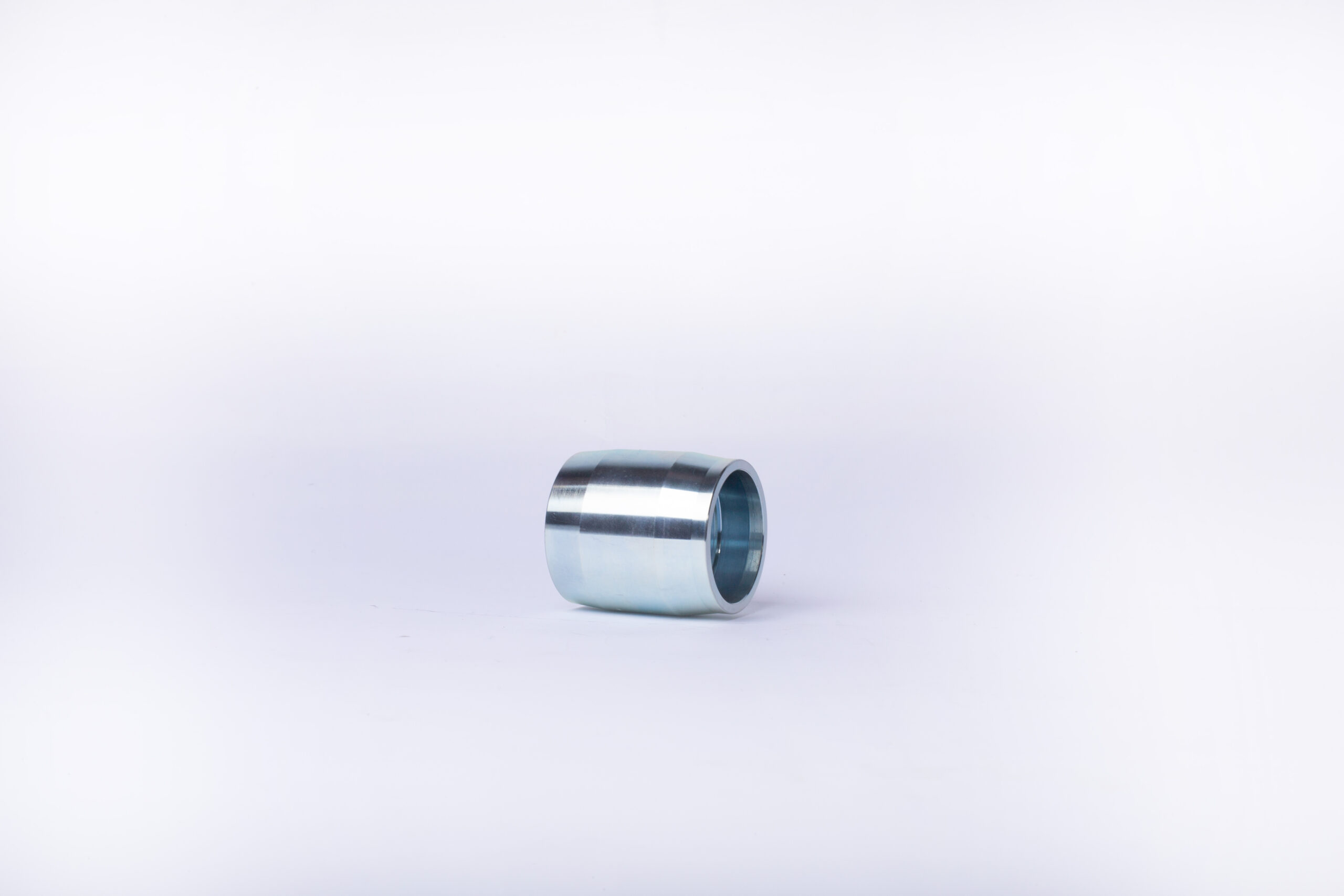

Product Name: Aluminum Forging

Product Type: Metal Forging

Material: Aluminum

Shape: Customized

Surface Treatment: Anodizing, Powder Coating, Spray Painting, Polishing

Production Process: Die Casting, Press Forging

Advantages:

1. High strength-to-weight ratio

2. Superior mechanical properties

3. Enhanced resistance to fatigue and wear

4. Tight dimensional tolerances

5. Cost-effective production

| Color | Silver |

|---|---|

| Material | Aluminum |

| MOQ | 1 Pcs |

| Sample | Available |

| Place of Origin | China |

Product Details

MINGYU Tech is a trusted manufacturer of high-quality china forged aluminum 8 lug wheels for the electronics industry. Our advanced forging processes and precision technology enable us to produce complex and precise forgings for a variety of electronic devices including computers, smartphones and consumer electronics. Our experienced team works closely with customers to provide customized solutions that meet their unique requirements. We are committed to providing customers with quality products and timely delivery.

china forged aluminum 8 lug wheels is a manufacturing process that involves shaping aluminum alloys into customized parts and components through the application of compressive force. The process involves heating the aluminum to a specific temperature and then using extreme pressure to force it into a specific mold or die. This results in a uniform and strong end product that is highly durable and resistant to wear and tear.

At MINGYU Tech, we specialize in china forged aluminum 8 lug wheels and have years of experience in producing high-quality parts and components for various industries. Our state-of-the-art equipment and skilled technicians allow us to provide our clients with top-notch products that meet their exact specifications.

| Place of Origin | China |

| Material | Metal Aluminium Steel Copper Brass |

| Process | Forging+machining+HT+finish Machining |

| Surface treatment | Polishing |

| Application | Machinery Parts |

| Product name | china forged aluminum 8 lug wheels |

| Certificate | TS16949/ISO9001 |

| Color | Customized Color |

| Quality Control | 100% Inspection |

| Lead Time | 14-35 Days |

| MOQ | 1 Piece |

| Supply Ability | 212414 Piece/Pieces per Month |

| Quantity (pieces) | > 466 |

| Lead time (days) | To be negotiated |

china forged aluminum 8 lug wheels FAQs Guide.

Our company is dedicated to providing high-quality china forged aluminum 8 lug wheels products to meet the needs of various industries. With advanced technology and skilled craftsmanship, we have become a leading manufacturer in the field of china forged aluminum 8 lug wheels. Our products are widely used in aerospace, automotive, and construction industries, just to name a few. We take great pride in our products as they are not only durable and reliable, but also lightweight and eco-friendly. Through this introduction, we hope to showcase the versatility and excellence of our china forged aluminum 8 lug wheels products. Thank you for choosing us as your trusted provider of top-notch china forged aluminum 8 lug wheels products.

1.Can china forged aluminum 8 lug wheelss be heat treated?

We have rich industry experience and professional knowledge, and have strong competitiveness in the market.

Yes, aluminum forgings can be heat treated. Heat treating is a process used to alter the physical and chemical properties of a material. It is commonly used to increase the strength and hardness of aluminum forgings.

2.What considerations should be taken into account when designing a product for china forged aluminum 8 lug wheels?

As one of the top china forged aluminum 8 lug wheels manufacturers in China, we take this very seriously.

1. Strength: Aluminum is a relatively soft metal, so it is important to consider the strength requirements of the product when designing for aluminum forging.

2. Heat Treatment: Aluminum is susceptible to heat treatment, so it is important to consider the desired properties of the product when designing for aluminum forging.

3. Grain Structure: Aluminum has a grain structure that can be affected by the forging process, so it is important to consider the desired grain structure of the product when designing for aluminum forging.

4. Tooling: Aluminum is a relatively soft metal, so it is important to consider the tooling requirements of the product when designing for aluminum forging.

5. Cost: Aluminum is a relatively inexpensive metal, so it is important to consider the cost of the product when designing for aluminum forging.

3.How does the cost of china forged aluminum 8 lug wheels compare to other metal forging processes?

We have advanced production equipment and technology to meet the needs of customers, and can provide customers with high quality, low priced china forged aluminum 8 lug wheels products.

The cost of aluminum forging is typically lower than other metal forging processes due to the lower cost of aluminum compared to other metals. Aluminum is also easier to work with than other metals, which can reduce the cost of labor and production time. Additionally, aluminum is a lightweight metal, which can reduce the cost of shipping and handling.

4.What are the properties of aluminum that make it suitable for forging?

We have the leading technology and innovation capabilities, and attach importance to employee training and development, and provide promotion opportunities.

1. Aluminum is lightweight and strong, making it ideal for forging.

2. Aluminum has a low melting point, making it easy to shape and form.

3. Aluminum is corrosion-resistant, making it suitable for outdoor applications.

4. Aluminum is malleable and ductile, making it easy to work with.

5. Aluminum is a good conductor of heat and electricity, making it suitable for electrical components.

6. Aluminum is non-magnetic, making it suitable for use in sensitive electronic equipment.

7. Aluminum is relatively inexpensive, making it a cost-effective choice for many applications.

5.About china forged aluminum 8 lug wheels overseas warehouse

Aluminum forging overseas warehouses are warehouses located in foreign countries that specialize in the storage and distribution of aluminum forgings. These warehouses are typically located in countries with a strong aluminum forging industry, such as China, India, and the United States. They provide a convenient and cost-effective way for companies to store and distribute their aluminum forgings, as well as to access the global market. The warehouses are typically equipped with the latest technology and equipment to ensure the highest quality of aluminum forgings.

6.What is the role of lubrication in china forged aluminum 8 lug wheels?

We adhere to the principle of quality first and have a complete production quality management system and quality inspection process.

Lubrication plays an important role in aluminum forging. It helps reduce friction between the metal and the die, which can reduce wear and tear on the die and help to improve the quality of the finished product. It also helps to reduce the amount of heat generated during the forging process, which can help to prevent the aluminum from becoming too hot and causing damage to the die. Finally, lubrication can help to reduce the amount of force required to form the aluminum, which can help to reduce the amount of energy used in the process.

7.How are defects identified and corrected during the china forged aluminum 8 lug wheels process?

Our products & services cover a wide range of areas and meet the needs of different fields.

Defects in aluminum forging can be identified and corrected through a variety of methods. Visual inspection is the most common method used to identify defects. This involves looking for surface irregularities, such as cracks, porosity, or other surface defects. Ultrasonic testing is also used to detect internal defects, such as voids, inclusions, or cracks. X-ray and radiographic testing can also be used to detect internal defects. Once a defect is identified, it can be corrected by reworking the part, using a different forging process, or by using a different material.

8.Are there any limitations to the size or complexity of products that can be forged from aluminum?

We adhere to the principle of integrity and transparency, and establish long -term relationships with partners, and we attach great importance to this detail.

Yes, there are limitations to the size and complexity of products that can be forged from aluminum. Aluminum is a relatively soft metal, so it is not suitable for forging large or complex parts. Additionally, aluminum has a low melting point, so it is not suitable for forging parts that require high temperatures.

9.About china forged aluminum 8 lug wheels raw materials

Aluminum forging raw materials are typically aluminum alloys that are heated and then shaped into a desired shape using a forging process. Common aluminum alloys used for forging include 6061, 7075, and 2024. These alloys are chosen for their strength, durability, and corrosion resistance. Other factors such as cost, availability, and machinability are also taken into consideration when selecting the right alloy for a particular application.

10.How does the cost of china forged aluminum 8 lug wheelss compare to casting or machining a similar part?

The cost of aluminum forgings is typically higher than casting or machining a similar part. This is because the process of forging is more complex and requires more specialized equipment and expertise. Additionally, the cost of raw materials for forging is typically higher than for casting or machining. However, the cost of aluminum forgings can be offset by the improved strength and durability of the part, as well as the potential for reduced machining time and cost.

11.Can non-CNC machining methods be used for finishing china forged aluminum 8 lug wheelss?

As one of the china forged aluminum 8 lug wheels market leaders, we are known for innovation and reliability.

Yes, non-CNC machining methods can be used for finishing aluminum forgings. These methods include grinding, sanding, polishing, and buffing.

12.Are there any unique thermal or electrical properties of china forged aluminum 8 lug wheelss?

We maintain a stable growth through reasonable capital operations, focus on industry development trends and cutting -edge technologies, and focus on product quality and safety performance.

Yes, aluminum forgings have unique thermal and electrical properties. Aluminum is a good conductor of electricity and heat, and its thermal conductivity is higher than that of steel. Aluminum also has a high strength-to-weight ratio, making it an ideal material for forging. Additionally, aluminum forgings are corrosion-resistant and have excellent fatigue strength.

13.About china forged aluminum 8 lug wheels payment method

Aluminum forging payment methods vary depending on the supplier. Common payment methods include cash, check, wire transfer, credit card, and PayPal. Some suppliers may also accept payment through financing options such as leasing or installment plans. It is important to discuss payment terms with the supplier prior to placing an order.

14.About china forged aluminum 8 lug wheels production capacity

Aluminum forging production capacity is determined by the size and complexity of the parts being produced, the type of forging process used, and the number of machines available. Generally, the larger the part, the more machines and time are required to produce it. The complexity of the part also affects the production capacity, as more complex parts require more time and machines to produce. Additionally, the type of forging process used can affect the production capacity, as some processes are more efficient than others.

15.About china forged aluminum 8 lug wheels production skills training

Aluminum forging production skills training is a type of training that teaches workers how to safely and effectively produce aluminum forgings. This type of training is important for workers in the aluminum forging industry, as it helps them to understand the process of forging aluminum and how to produce quality products. The training typically covers topics such as safety, tooling, and the proper use of equipment. It also covers topics such as heat treatment, metallurgy, and the different types of aluminum alloys used in forging. Additionally, the training may cover topics such as quality control and inspection, as well as the different types of finishing processes used in aluminum forging.

16.What safety precautions should be taken when working with hot aluminum during the forging process?

We focus on providing high china forged aluminum 8 lug wheels quality products and services.

1. Wear protective clothing, such as heat-resistant gloves, long sleeves, and safety glasses.

2. Use tongs or other tools to handle the hot aluminum.

3. Ensure that the work area is well-ventilated and free of combustible materials.

4. Have a fire extinguisher nearby in case of an emergency.

5. Keep a bucket of water nearby to cool down the aluminum if necessary.

6. Use a heat shield to protect yourself from the heat of the aluminum.

7. Do not forge aluminum near any open flames or sparks.

8. Do not forge aluminum in an enclosed space.

9. Do not forge aluminum near any combustible materials.

10. Make sure to keep the aluminum away from any flammable liquids.

Tag:aluminum forging press,aluminum alloy forging,forging dies for sheet aluminum,forged aluminum melting point

Product Inquiry

We will respond within 12 hours, please pay attention to the email “@163.com” or “@alumforge.com”.

Also, you can go to the Contact Page, which provides a more detailed form, if you have more inquiries for products or would like to obtain OEM service.

Our sales experts will respond within 24 hours, please pay attention to the email with the suffix “@163.com”.