In the ever-evolving automotive industry, efficiency and power output are critical factors that define the performance of a vehicle. Among the various components that contribute to these characteristics, piston rods play a pivotal role. This article delves into the significance of piston rods in enhancing engine efficiency and power output, with a particular focus on MINGYU, a renowned aluminum forge manufacturer, known for producing high-quality piston rods for automotive applications.

The Role of Piston Rods in Automotive Engines

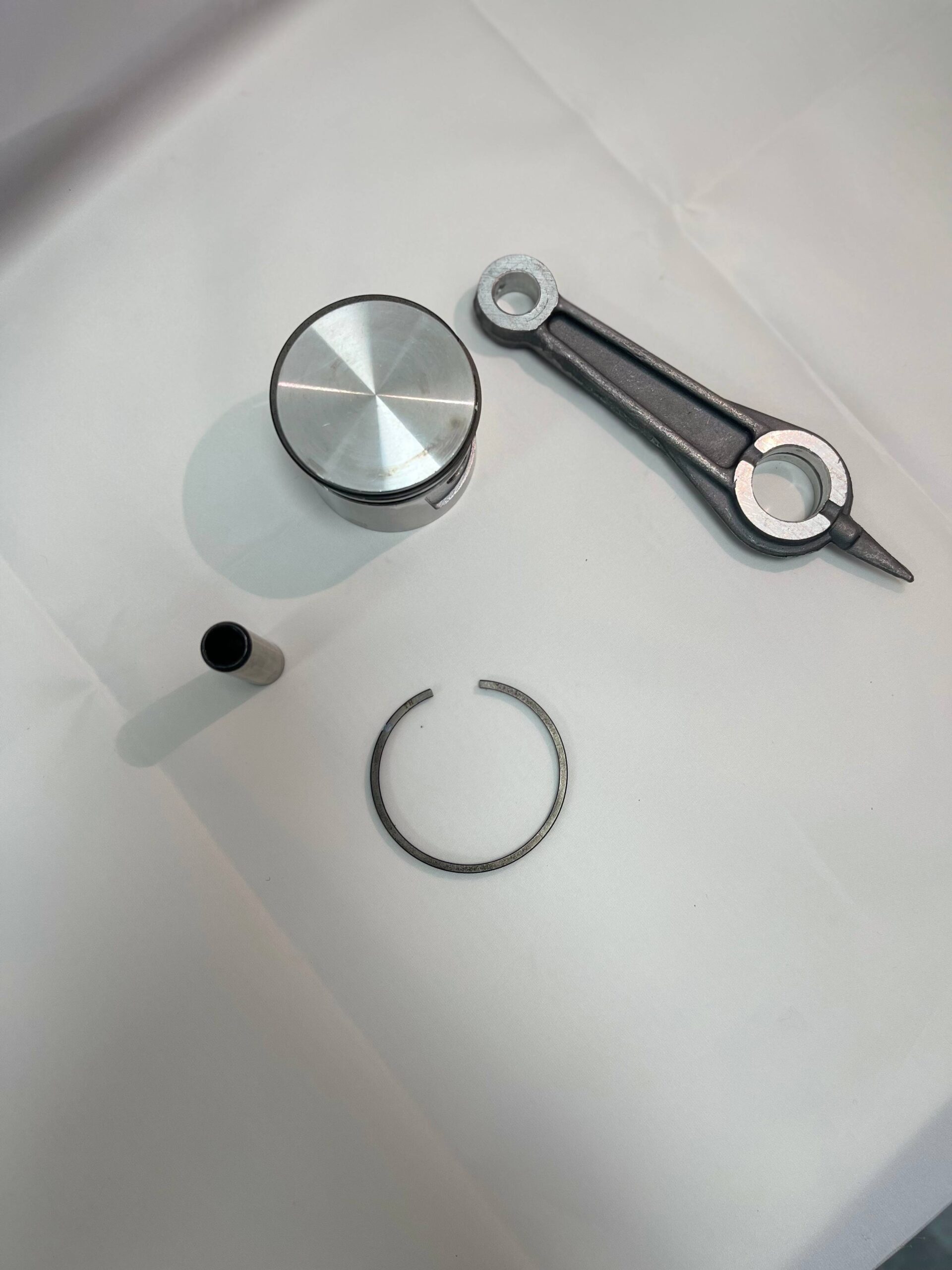

Piston rods, also known as connecting rods, are integral components of an internal combustion engine. They serve as the crucial link between the piston and the crankshaft, converting the linear motion of the piston into the rotational motion required to drive the vehicle. This conversion is essential for the engine’s operation, making piston rods a vital component in the powertrain.

The efficiency and performance of an engine heavily depend on the design and material of the piston rods. A well-designed piston rod can significantly reduce the engine’s frictional losses, enhance fuel efficiency, and increase power output. Consequently, manufacturers like MINGYU invest heavily in research and development to produce piston rods that meet the high standards required by modern automotive engines.

MINGYU: A Leader in Aluminum Forge Manufacturing

MINGYU has established itself as a leader in the aluminum forging industry, specializing in the production of high-performance piston rods. The company’s commitment to quality and innovation has earned it a reputation for excellence in automotive engineering. MINGYU’s piston rods are renowned for their durability, lightweight properties, and superior performance, making them a preferred choice for automakers worldwide.

Aluminum forging is a process that involves shaping aluminum alloys under high pressure to achieve the desired form and structure. This method is favored for its ability to produce components with excellent mechanical properties and a high strength-to-weight ratio. MINGYU’s expertise in aluminum forging enables the production of piston rods that not only enhance engine efficiency but also contribute to overall vehicle performance.

Enhancing Engine Efficiency

Engine efficiency is a crucial aspect of automotive performance, influencing fuel consumption and emissions. Piston rods play a significant role in optimizing engine efficiency through the following mechanisms:

- Reduced Friction: MINGYU’s aluminum-forged piston rods are designed to minimize friction between the piston and the cylinder walls. This reduction in friction leads to less energy loss, thereby improving the engine’s overall efficiency.

- Lightweight Design: The use of aluminum in piston rod manufacturing results in a lighter component compared to traditional steel rods. A lighter piston rod reduces the engine’s reciprocating mass, allowing for quicker acceleration and improved fuel efficiency.

- Precision Engineering: MINGYU employs advanced engineering techniques to ensure precise dimensions and tolerances in their piston rods. This precision reduces mechanical losses and enhances the smooth operation of the engine.

By focusing on these aspects, MINGYU’s piston rods contribute significantly to the efficiency of modern automotive engines, helping manufacturers meet stringent fuel economy and emission standards.

Boosting Power Output

In addition to enhancing efficiency, piston rods are critical in maximizing an engine’s power output. MINGYU’s piston rods achieve this through several key features:

- High Strength-to-Weight Ratio: The aluminum forging process employed by MINGYU results in piston rods with a superior strength-to-weight ratio. This characteristic allows the engine to handle higher loads and speeds, increasing power output without compromising reliability.

- Enhanced Durability: MINGYU’s piston rods are designed to withstand the high stresses and temperatures encountered in high-performance engines. This durability ensures that the engine can operate at peak power levels for extended periods.

- Optimized Geometry: The geometry of the piston rod is optimized for maximum efficiency and power transfer. MINGYU uses computer-aided design (CAD) and finite element analysis (FEA) to refine the shape and structure of their piston rods, ensuring optimal performance.

These features make MINGYU’s piston rods an ideal choice for high-performance automotive applications, where maximizing power output is a priority.

Case Study: MINGYU’s Impact on Automotive Performance

To illustrate the impact of MINGYU’s piston rods on automotive performance, consider a case study involving a leading automaker seeking to enhance the performance of their flagship sports car. The automaker partnered with MINGYU to develop custom piston rods tailored to their engine specifications.

The result was a significant improvement in both efficiency and power output. The lightweight and durable piston rods allowed the engine to achieve higher RPMs, translating to increased horsepower and torque. Additionally, the reduction in friction and weight contributed to a notable improvement in fuel efficiency, aligning with the automaker’s sustainability goals.

Conclusion

In conclusion, piston rods are a critical component in enhancing engine efficiency and power output in automotive applications. MINGYU, as a leading aluminum forge manufacturer, has demonstrated its expertise in producing high-performance piston rods that meet the demands of modern engines. Through advanced forging techniques, precision engineering, and a commitment to quality, MINGYU continues to set the standard for piston rod manufacturing in the automotive industry.

As automakers strive to balance performance, efficiency, and sustainability, the role of piston rods becomes increasingly important. With companies like MINGYU at the forefront of innovation, the future of automotive engineering looks promising, with continued advancements in engine technology and performance.

Ultimately, the collaboration between automakers and specialized manufacturers like MINGYU will drive the evolution of the automotive industry, delivering vehicles that are not only powerful and efficient but also environmentally friendly.

By understanding the intricacies of piston rod design and manufacturing, stakeholders in the automotive industry can make informed decisions that enhance vehicle performance and contribute to a sustainable future. MINGYU’s dedication to excellence in aluminum forging exemplifies the potential of innovation in achieving these goals.

Tags:assempbly parts others,aluminum forging,aluminum machining