Rebuilding an engine is a meticulous process that requires precision, patience, and the right set of tools. One of the most crucial components in this process is the piston tool set. When used correctly, it can help you rebuild your engine efficiently and maximize its power output. In this article, we will explore how to properly use a piston tool set, with insights from MINGYU, a renowned Aluminum Forge manufacturer.

The Importance of a Piston Tool Set in Engine Rebuilding

A piston tool set is indispensable in the engine rebuilding process. It comprises various tools designed to handle the pistons, which are critical components of an engine. Pistons convert the energy from combustion into mechanical power, driving the crankshaft and, ultimately, the vehicle. Therefore, ensuring that pistons are installed correctly and function optimally is vital for engine performance.

MINGYU, a leader in aluminum forging, emphasizes the quality and precision of piston tool sets. Their expertise ensures that each tool in the set is crafted to meet the highest standards, providing users with the reliability they need during engine rebuilds.

Components of a Piston Tool Set

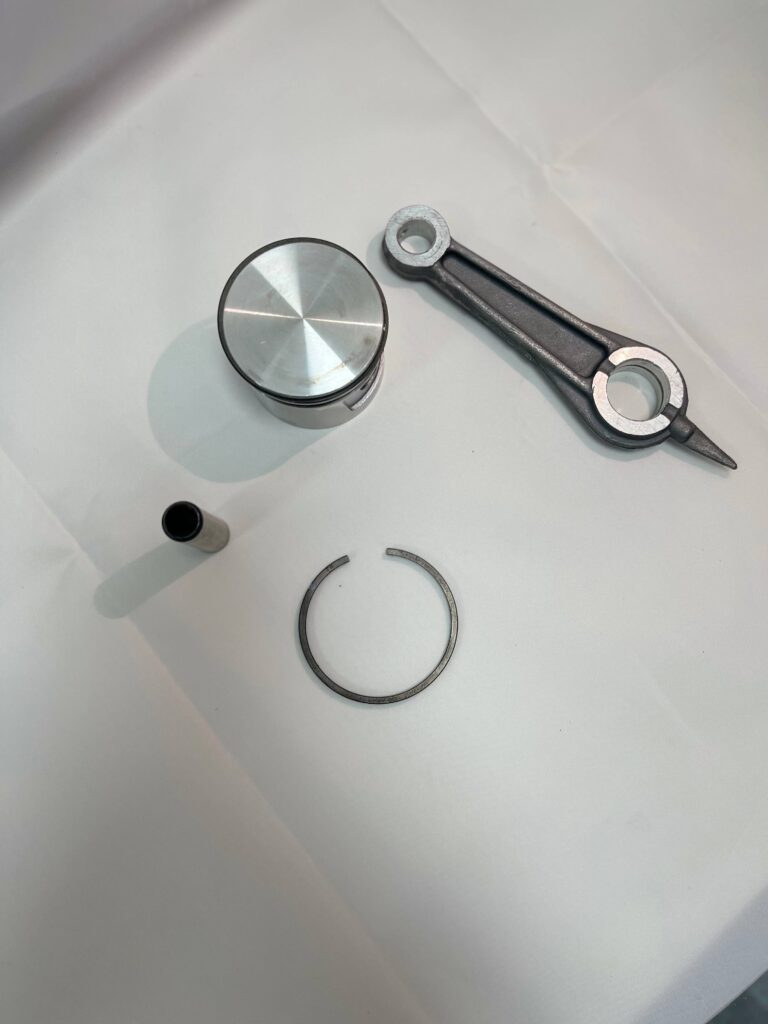

A comprehensive piston tool set typically includes the following components:

- Piston Ring Compressor: This tool is used to compress the piston rings, allowing the piston to be inserted into the cylinder bore without damaging the rings.

- Piston Ring Expander: It helps in safely removing and installing piston rings without causing any deformation.

- Piston Pin Removal Tool: This tool facilitates the removal and installation of the piston pin, which connects the piston to the connecting rod.

- Ring Groove Cleaner: Essential for cleaning the grooves on the piston where the rings sit, ensuring a proper fit and function.

- Torque Wrench: Used to apply the correct amount of torque to fasteners, ensuring secure connections without over-tightening.

Each of these tools plays a vital role in the rebuild process, and understanding their use is crucial for achieving optimal results.

Step-by-Step Guide to Using a Piston Tool Set

Step 1: Preparing the Work Area

Before beginning the rebuild, prepare your work area. Ensure it is clean, well-lit, and organized. Gather all necessary tools and components, including your MINGYU piston tool set, and lay them out for easy access.

Step 2: Removing the Existing Pistons

Start by removing the existing pistons from the engine. Use the piston pin removal tool to carefully detach the piston from the connecting rod. Take note of the orientation and arrangement of the pistons, as this will be important during reassembly.

Step 3: Cleaning and Inspecting the Components

Once the pistons are removed, clean all components thoroughly. Use the ring groove cleaner to remove any carbon deposits or debris from the piston grooves. Inspect the pistons, rings, and cylinder walls for wear or damage. Replace any components that are worn or damaged.

Step 4: Installing the Piston Rings

With the piston ring expander, carefully install the new piston rings onto each piston. Ensure the rings are seated properly in their respective grooves. Pay attention to the ring end gaps and ensure they are staggered according to the manufacturer’s specifications to prevent blow-by.

Step 5: Compressing the Piston Rings

Use the piston ring compressor to compress the rings, allowing the piston to be inserted into the cylinder. Position the compressor over the piston, tighten it until the rings are compressed, and gently tap the piston into the cylinder bore with a soft mallet.

Step 6: Reattaching the Connecting Rod

Once the piston is in place, reattach the connecting rod using the piston pin. Ensure the rod is properly aligned and secured. Use a torque wrench to tighten the rod bolts to the manufacturer’s specifications, ensuring a secure connection.

Maximizing Engine Power with Precision and Quality

After the pistons are installed, continue with the rest of the engine rebuild process, including installing the cylinder head, timing components, and other necessary parts. Throughout this process, precision is key. Use the torque wrench to ensure all fasteners are tightened to the correct specifications.

MINGYU’s commitment to quality in their aluminum forged components means that when you use their piston tool set, you’re ensuring the best possible fit and function for your engine rebuild. This precision translates to enhanced engine performance and power.

Final Checks and Testing

Once the engine is fully assembled, perform a series of checks to ensure everything is in order. Rotate the engine manually to check for any binding or unusual resistance. Verify that all components are properly installed and secured.

After these checks, start the engine and monitor its performance. Listen for any unusual noises and check for leaks. A well-rebuilt engine should run smoothly and efficiently, delivering the power and performance you expect.

Conclusion

Rebuilding an engine is a complex task that demands attention to detail and the right tools. A piston tool set is essential for handling one of the most critical components of your engine—the pistons. By following the steps outlined in this article and using a high-quality set from MINGYU, you can ensure a successful rebuild and maximize your engine’s power.

Investing in a reliable piston tool set and adhering to best practices in engine rebuilding will pay off in the form of enhanced performance, longevity, and satisfaction with your vehicle. With MINGYU’s expertise in aluminum forging, you can trust that you’re using tools crafted for excellence.

Remember, patience and precision are your best allies in this process. Take your time, follow the steps carefully, and enjoy the rewards of a well-rebuilt engine.