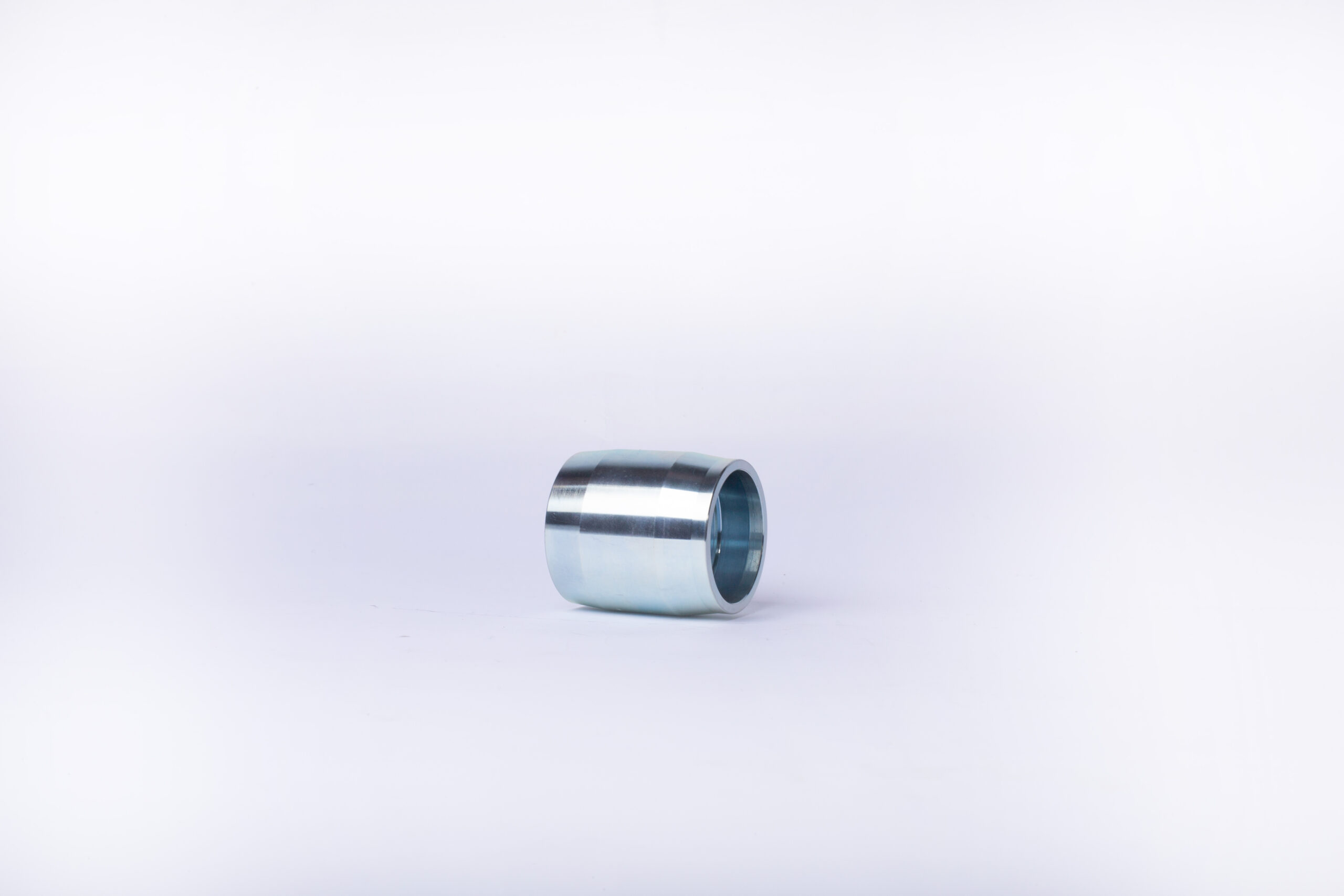

Product Name: Aluminum Forging

Product Type: Metal Forging

Material: Aluminum

Shape: Customized

Surface Treatment: Anodizing, Powder Coating, Spray Painting, Polishing

Production Process: Die Casting, Press Forging

Advantages:

1. High strength-to-weight ratio

2. Superior mechanical properties

3. Enhanced resistance to fatigue and wear

4. Tight dimensional tolerances

5. Cost-effective production

| Color | Silver |

|---|---|

| Material | Aluminum |

| MOQ | 1 Pcs |

| Sample | Available |

| Place of Origin | China |

Product Details

MINGYU Tech. is a leading manufacturer of custom aluminum parts for various industries including medical, telecommunications and defense. With over 20 years of experience, we have developed extensive expertise in aircraft aluminum machining including 6061, 7075 and 2024. Our state-of-the-art factory is equipped with the latest CNC machine tools and inspection equipment to ensure the highest level of machining accuracy and quality. We also offer secondary services such as heat treatment, electroplating and passivation to meet specific customer requirements.

One of the main products produced through aircraft aluminum machining is aluminum sheets. These sheets are widely used in the construction industry for roofing, siding, and insulation purposes. They are also used in the automotive industry for body panels and in the packaging industry for making cans and containers.

Another commonly produced product through aircraft aluminum machining is aluminum extrusions. These are long, hollow shapes used in various industries such as construction, transportation, and electronics. They are lightweight, strong, and can be easily fabricated into different shapes and sizes. aircraft aluminum machining is also used in the production of high precision components used in the aerospace and defense industries. The lightweight nature of aluminum makes it an ideal choice for these industries, as it reduces the weight of the final product without compromising its strength and durability.

| Brand | MINGYU TechMINGYU Tech |

| Original | China |

| Capacity | 1349Ton/Month |

| Thickness | 0.6mm and above, or Customized |

| Length | 3-7Meter |

| Hardness | >=8HW |

| Color | Silver,White,Black,Grey,Bronze,Champagne,Wood and any as requested |

aircraft aluminum machining FAQs Guide.

Our company specializes in providing high-quality aircraft aluminum machining services for a variety of industries. With years of experience, state-of-the-art equipment, and a dedicated team, we pride ourselves on delivering precision and top-notch results for our customers. we will outline our capabilities and processes, and provide examples of the aluminum products we can create. We are confident that our aircraft aluminum machining services will meet and exceed your expectations.

1.What is aluminum machining?

We have advantages in marketing and channel expansion. Suppliers have established good cooperative relations, continuously improved workflows, improved efficiency and productivity, and provided customers with high -quality products and services.

Aluminum machining is the process of cutting, drilling, grinding, and shaping aluminum materials to create parts and components for a variety of applications. It is a process that requires specialized tools and techniques to ensure accuracy and precision. Aluminum machining is used in a variety of industries, including aerospace, automotive, and medical.

2.Can aluminum be machined to create threads or other internal features?

We continue to invest in research and development and continue to launch innovative products.

Yes, aluminum can be machined to create threads or other internal features. Machining aluminum requires specialized tools and techniques, such as tapping, thread milling, and drilling. It is important to use the correct cutting tools and speeds to ensure a successful outcome.

3.Is aluminum recycling feasible in the machining industry?

We have flexible production capacity. Whether you are large orders or small orders, you can produce and release goods in a timely manner to meet customer needs.

Yes, aluminum recycling is feasible in the machining industry. Aluminum is a highly recyclable material, and it is often used in machining operations due to its strength and light weight. Recycling aluminum can help reduce costs and conserve resources, and it can also help reduce waste and pollution.

4.What factors affect the speed and efficiency of aluminum machining?

We are a professional aircraft aluminum machining company dedicated to providing high quality products and services.

1. Tooling: The type of tooling used for aluminum machining can have a significant impact on the speed and efficiency of the process. For example, using a high-speed steel (HSS) tool can provide faster cutting speeds than a carbide tool.

2. Feed Rate: The feed rate of the cutting tool is also important for aluminum machining. A higher feed rate can increase the speed of the process, but it can also lead to increased tool wear and decreased tool life.

3. Cutting Fluids: The use of cutting fluids can help to reduce friction and heat during aluminum machining, which can improve the speed and efficiency of the process.

4. Cutting Parameters: The cutting parameters, such as the spindle speed, feed rate, and depth of cut, can all affect the speed and efficiency of aluminum machining.

5. Workpiece Material: The type of aluminum being machined can also affect the speed and efficiency of the process. For example, softer aluminum alloys can be machined faster than harder alloys.

5.Can aluminum be machined to tight tolerances?

We focus on teamwork and communication to achieve common goals, We attach great importance to this detail.

Yes, aluminum can be machined to tight tolerances. Aluminum is a relatively soft metal, which makes it easy to machine and shape into complex parts with tight tolerances. Machining aluminum requires specialized tools and techniques, but with the right equipment and expertise, aluminum can be machined to very precise tolerances.

6.What are some common problems encountered during aluminum machining?

We should enjoy a good reputation in the industry, and we can increase the added value of the products of cooperative customers through technological innovation.

1. Tool wear: Aluminum is a soft metal, which can cause tools to wear quickly.

2. Chip clogging: Aluminum chips can easily clog up the cutting area, leading to poor surface finish and reduced tool life.

3. Heat buildup: Aluminum is a good conductor of heat, which can cause the tool and workpiece to heat up quickly. This can lead to tool failure and reduced accuracy.

4. Vibration: Aluminum is a lightweight material, which can cause vibration during machining. This can lead to poor surface finish and reduced accuracy.

5. Poor surface finish: Aluminum is a soft metal, which can cause a poor surface finish. This can be improved by using a higher cutting speed and a sharper tool.

7.How long has aluminum machining been around?

Being one of the top aircraft aluminum machining manufacturers in China, We attach great importance to this detail.

Aluminum machining has been around since the late 19th century. The first aluminum machining process was developed in 1885 by Charles Martin Hall and Paul Héroult.

8.What are some considerations when machining aluminum for aerospace applications?

1. Use high-speed steel or carbide tools with sharp cutting edges to reduce cutting forces and minimize tool wear.

2. Use coolant to reduce heat buildup and improve chip evacuation.

3. Use a low feed rate to reduce cutting forces and minimize tool wear.

4. Use a high spindle speed to reduce cutting forces and minimize tool wear.

5. Use a high depth of cut to reduce cutting forces and minimize tool wear.

6. Use a high cutting speed to reduce cutting forces and minimize tool wear.

7. Use a high-pressure coolant system to reduce heat buildup and improve chip evacuation.

8. Use a rigid machine setup to reduce vibration and improve surface finish.

9. Use a high-quality cutting tool material to reduce tool wear and improve surface finish.

10. Use a high-quality cutting tool geometry to reduce cutting forces and improve surface finish.

9.How does the design of the part affect the machining process for aluminum?

The design of the part affects the machining process for aluminum in several ways. The shape of the part will determine the type of tooling and cutting parameters that are used. For example, a part with complex geometries may require a more specialized tooling setup than a part with simpler geometries. Additionally, the size of the part will determine the speed and feed rates that are used during the machining process. The material properties of aluminum also affect the machining process, as aluminum is a softer material than other metals and requires slower speeds and feeds to prevent tool wear and tear. Finally, the surface finish of the part will determine the type of finishing operations that are used, such as polishing or deburring.

10.What safety precautions should be taken when machining aluminum?

We pay attention to employee development and benefits, and provide a good working environment in order to improve the efficiency of employees and improve the quality management of aircraft aluminum machining products.

1. Wear appropriate safety gear, such as safety glasses, gloves, and a face shield.

2. Use a cutting fluid to reduce heat and friction.

3. Use a slower cutting speed and feed rate.

4. Use sharp cutting tools and replace them regularly.

5. Use a coolant to reduce heat and friction.

6. Use a vacuum to collect chips and dust.

7. Use a chip guard to protect the operator from flying chips.

8. Use a flood coolant to reduce heat and friction.

9. Use a chip breaker to reduce the size of chips.

10. Use a chip deflector to direct chips away from the operator.

11.Can aluminum be machined at high speeds?

We are centered on customers and always pay attention to customers’ needs for aircraft aluminum machining products.

Yes, aluminum can be machined at high speeds. However, it is important to use the right cutting tools and speeds to ensure that the aluminum is machined correctly and efficiently.

12.Can additives be used in the cutting fluid when machining aluminum?

Yes, additives can be used in the cutting fluid when machining aluminum. Additives can help reduce friction, improve lubricity, and reduce heat buildup. However, it is important to use the correct type of additive for the specific application, as some additives may be incompatible with aluminum.

13.How do advances in technology affect aluminum machining?

We should have a stable supply chain and logistics capabilities, and provide customers with high -quality, low -priced aircraft aluminum machining products.

Advances in technology have had a significant impact on aluminum machining. New technologies such as CNC machining, laser cutting, and waterjet cutting have allowed for more precise and efficient machining of aluminum components. Additionally, new materials such as aluminum alloys have been developed that are more suitable for machining, allowing for more complex shapes and designs to be created. Finally, advances in software have allowed for more efficient programming of machining processes, resulting in faster production times and improved accuracy.

14.How can warping and distortion be prevented during aluminum machining?

We have advanced production equipment and technology to meet the needs of customers, and can provide customers with high quality, low priced aircraft aluminum machining products.

Warping and distortion during aluminum machining can be prevented by using a rigid setup, using a sharp cutting tool, using a coolant, and using a slower cutting speed. Additionally, using a high-quality cutting tool and ensuring that the cutting tool is properly aligned with the workpiece can help reduce warping and distortion. Finally, using a chip breaker or chip breaker insert can help reduce the amount of heat generated during machining, which can help reduce warping and distortion.

Tag:china cnc aluminum machining,aluminum machining parts manufacturer,aluminum machining grade

Product Inquiry

We will respond within 12 hours, please pay attention to the email “@163.com” or “@alumforge.com”.

Also, you can go to the Contact Page, which provides a more detailed form, if you have more inquiries for products or would like to obtain OEM service.

Our sales experts will respond within 24 hours, please pay attention to the email with the suffix “@163.com”.