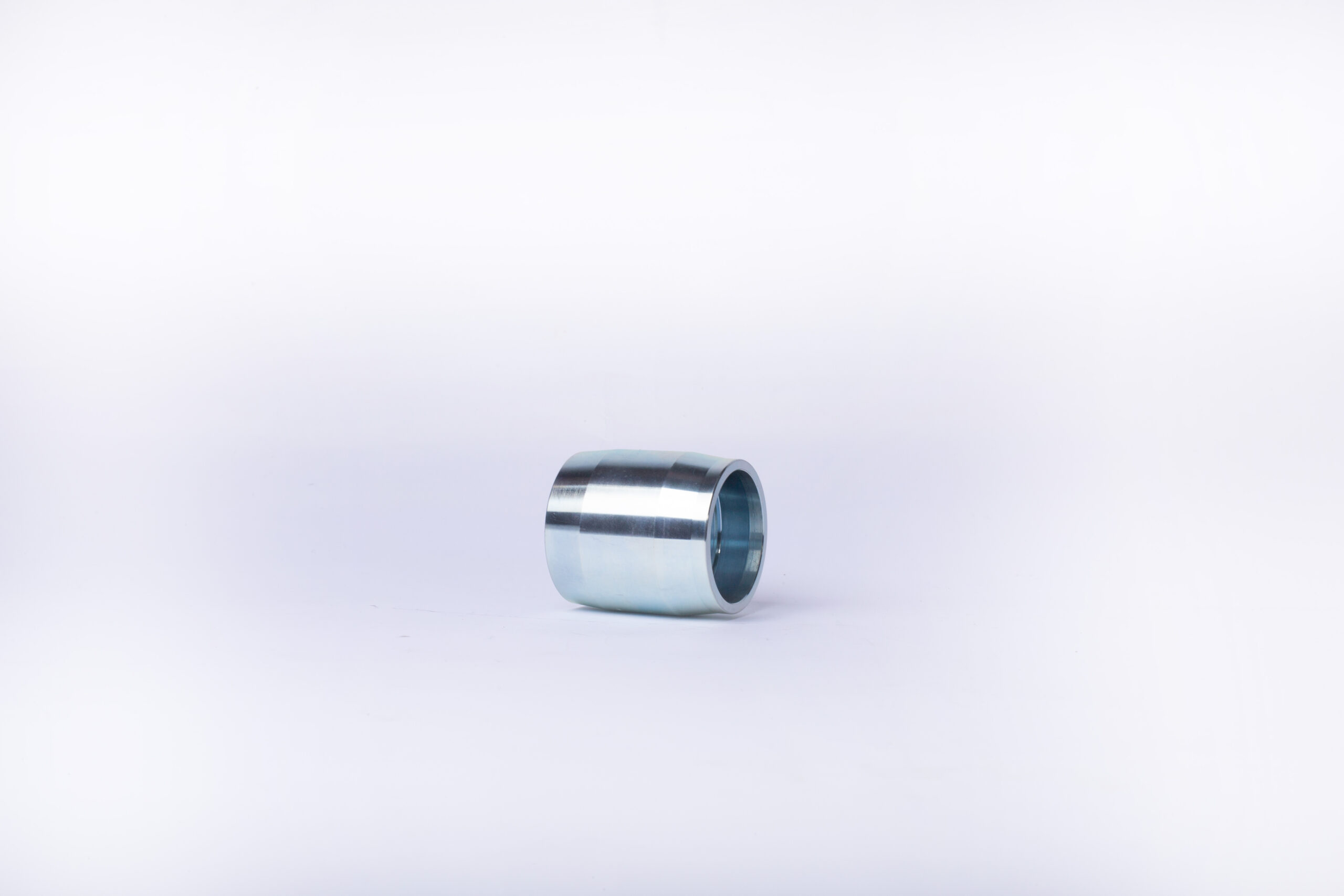

Product Name: Aluminum Forging

Product Type: Metal Forging

Material: Aluminum

Shape: Customized

Surface Treatment: Anodizing, Powder Coating, Spray Painting, Polishing

Production Process: Die Casting, Press Forging

Advantages:

1. High strength-to-weight ratio

2. Superior mechanical properties

3. Enhanced resistance to fatigue and wear

4. Tight dimensional tolerances

5. Cost-effective production

| Color | Silver |

|---|---|

| Material | Aluminum |

| MOQ | 1 Pcs |

| Sample | Available |

| Place of Origin | China |

Product Details

With more than 20 years of cnc aluminum machining parts pricelist experience, MINGYU Tech. is a trusted aluminum processing solution provider for many industries including aerospace, marine and energy. We specialize in complex multi-axis machining and can machine a variety of aluminum alloys, from soft and ductile to hard and brittle. Our modern 120,000 square foot facility is equipped with the latest CNC machine tools and inspection equipment, allowing us to produce high quality parts to tight tolerances. We also provide engineering support and value-added services such as assembly and kitting.

One of the main advantages of cnc aluminum machining parts pricelist is its lightweight yet durable nature. As a non-ferrous metal, aluminum is much lighter than steel, making it ideal for applications where weight is a concern, such as in the aerospace and automotive industries. Despite its lightweight, aluminum is also strong and can withstand high levels of stress and pressure, making it suitable for use in structural components.

cnc aluminum machining parts pricelist also offers excellent corrosion resistance. The metal naturally forms a thin oxide layer on its surface, protecting it from corrosion and making it ideal for use in harsh environments or outdoor applications. This resistance to corrosion makes aluminum a cost-effective and low-maintenance material for many industrial and commercial applications.

| Brand | MINGYU TechMINGYU Tech |

| Original | China |

| Capacity | 1251Ton/Month |

| Thickness | 0.5mm and above, or Customized |

| Length | 3-7.6Meter |

| Hardness | >=8HW |

| Color | Silver,White,Black,Grey,Bronze,Champagne,Wood and any as requested |

cnc aluminum machining parts pricelist FAQs Guide.

Our company specializes in providing high-quality cnc aluminum machining parts pricelist services for a variety of industries. With years of experience, state-of-the-art equipment, and a dedicated team, we pride ourselves on delivering precision and top-notch results for our customers. we will outline our capabilities and processes, and provide examples of the aluminum products we can create. We are confident that our cnc aluminum machining parts pricelist services will meet and exceed your expectations.

1.Can aluminum be machined at high speeds?

We are centered on customers and always pay attention to customers’ needs for cnc aluminum machining parts pricelist products.

Yes, aluminum can be machined at high speeds. However, it is important to use the right cutting tools and speeds to ensure that the aluminum is machined correctly and efficiently.

2.What are some examples of products created through aluminum machining?

We have a first -class management team, and we pay attention to teamwork to achieve common goals.

Examples of products created through aluminum machining include:

1. Automotive parts such as engine blocks, cylinder heads, and transmission housings

2. Aerospace components such as aircraft wings, fuselages, and landing gear

3. Medical equipment such as surgical instruments, prosthetics, and implants

4. Electronics components such as circuit boards, connectors, and heat sinks

5. Industrial components such as valves, pumps, and machine parts

6. Architectural components such as window frames, door frames, and handrails

3.What are the safety hazards associated with aluminum machining?

We have the leading technology and innovation capabilities, and attach importance to employee training and development, and provide promotion opportunities.

1. Fire and Explosion Risk: Aluminum is highly flammable and can easily ignite when exposed to sparks or open flames.

2. Fumes and Dust: Aluminum machining produces hazardous fumes and dust that can be harmful to workers if inhaled.

3. Heat: Aluminum machining generates a lot of heat, which can cause burns if not properly managed.

4. Noise: Aluminum machining can be very loud, which can cause hearing damage if not properly managed.

5. Sharp Edges: Aluminum machining can produce sharp edges that can cause cuts and lacerations if not properly managed.

4.How does aluminum machining compare to other common materials such as steel or titanium?

We are a new cnc aluminum machining parts pricelist manufacturer.

Aluminum machining is generally easier than machining steel or titanium due to its lower strength and hardness. Aluminum is also more ductile and malleable than steel or titanium, which makes it easier to shape and form. Aluminum is also much lighter than steel or titanium, which makes it easier to handle and transport. However, aluminum is more prone to corrosion than steel or titanium, so it requires more frequent maintenance and protection.

5.Can aluminum be machined using non-traditional processes, such as EDM or laser cutting?

We actively participate in the cnc aluminum machining parts pricelist industry associations and organization activities. The corporate social responsibility performed well, and the focus of brand building and promotion

Yes, aluminum can be machined using non-traditional processes such as EDM (electrical discharge machining) and laser cutting. EDM is a process that uses electrical sparks to cut away material from a workpiece, while laser cutting uses a focused beam of light to cut away material. Both processes are used to create intricate shapes and patterns in aluminum.

6.Are there alternatives to traditional machining for shaping and forming aluminum?

Yes, there are several alternatives to traditional machining for shaping and forming aluminum. These include:

-Casting: Casting is a process in which molten aluminum is poured into a mold and allowed to cool and solidify. This is a great way to create complex shapes and parts with a high degree of accuracy.

-Extrusion: Extrusion is a process in which aluminum is forced through a die to create a desired shape. This is a great way to create parts with a consistent cross-section.

-Forging: Forging is a process in which aluminum is heated and then hammered or pressed into a desired shape. This is a great way to create parts with a high degree of strength and durability.

-Stamping: Stamping is a process in which aluminum is cut and formed into a desired shape using a die. This is a great way to create parts with a high degree of accuracy and repeatability.

7.Can aluminum be machined to create prototypes or one-of-a-kind parts?

We maintain a stable growth through reasonable capital operations, focus on industry development trends and cutting -edge technologies, and focus on product quality and safety performance.

Yes, aluminum can be machined to create prototypes or one-of-a-kind parts. Aluminum is a popular material for machining because it is lightweight, strong, and corrosion-resistant. It is also relatively easy to machine, making it a great choice for creating custom parts.

8.Can aluminum be machined to create both simple and complex parts?

Yes, aluminum can be machined to create both simple and complex parts. Machining aluminum is a popular process for creating parts because it is relatively easy to work with and is a lightweight material. Machining aluminum can be done with a variety of tools, including lathes, milling machines, and drill presses.

9.How do advances in technology affect aluminum machining?

We should have a stable supply chain and logistics capabilities, and provide customers with high -quality, low -priced cnc aluminum machining parts pricelist products.

Advances in technology have had a significant impact on aluminum machining. New technologies such as CNC machining, laser cutting, and waterjet cutting have allowed for more precise and efficient machining of aluminum components. Additionally, new materials such as aluminum alloys have been developed that are more suitable for machining, allowing for more complex shapes and designs to be created. Finally, advances in software have allowed for more efficient programming of machining processes, resulting in faster production times and improved accuracy.

10.What impact does the speed of cutting have on the final product in aluminum machining?

The speed of cutting has a significant impact on the final product in aluminum machining. A slower cutting speed will produce a better finish, while a faster cutting speed will produce a rougher finish. Slower cutting speeds also reduce the risk of tool breakage and heat build-up, which can cause warping and other defects. Additionally, slower cutting speeds can help to reduce the amount of material removed, which can help to reduce costs.

11.Can different types of coatings be applied to aluminum after machining?

We continue to improve cnc aluminum machining parts pricelist products and processes to improve efficiency.

Yes, different types of coatings can be applied to aluminum after machining. Common coatings include anodizing, powder coating, and painting. Anodizing is a process that creates a protective oxide layer on the surface of the aluminum, while powder coating is a process that applies a dry powder to the surface of the aluminum and then bakes it to create a hard finish. Painting is a process that applies a liquid paint to the surface of the aluminum and then bakes it to create a hard finish.

12.How long has aluminum machining been around?

Being one of the top cnc aluminum machining parts pricelist manufacturers in China, We attach great importance to this detail.

Aluminum machining has been around since the late 19th century. The first aluminum machining process was developed in 1885 by Charles Martin Hall and Paul Héroult.

13.How does the cost of aluminum machining compare to other metals?

We have rich industry experience and professional knowledge, and have strong competitiveness in the market.

The cost of aluminum machining is generally lower than other metals due to its low density and high thermal conductivity. Aluminum is also easier to machine than other metals, which can reduce machining costs. Additionally, aluminum is a non-ferrous metal, meaning it does not contain iron, which can reduce the cost of machining due to the lack of need for specialized tools.

14.How does the thickness of the aluminum affect the machining process?

The thickness of the aluminum affects the machining process in several ways. Thicker aluminum requires more cutting force and can cause more wear on the cutting tools. It also requires more time to machine, as the cutting tools must move more slowly to ensure a clean cut. Additionally, thicker aluminum can cause more vibration during the machining process, which can lead to poor surface finish and accuracy.

15.What industries commonly use aluminum machining?

We have broad development space in domestic and foreign markets. cnc aluminum machining parts pricelist have great advantages in terms of price, quality, and delivery date.

Aluminum machining is commonly used in a variety of industries, including aerospace, automotive, medical, electronics, and defense. It is also used in the production of consumer goods such as appliances, sporting goods, and furniture.

16.Can aluminum be machined to create both large and small parts?

Yes, aluminum can be machined to create both large and small parts. Machining aluminum is a popular process for creating parts of all sizes, from tiny components to large structural components. Machining aluminum is relatively easy compared to other metals, and it can be used to create complex shapes and intricate details.

Tag:aluminum machining stress relief,aluminum machining service manufacturers,aluminum machining part service provider

Product Inquiry

We will respond within 12 hours, please pay attention to the email “@163.com” or “@alumforge.com”.

Also, you can go to the Contact Page, which provides a more detailed form, if you have more inquiries for products or would like to obtain OEM service.

Our sales experts will respond within 24 hours, please pay attention to the email with the suffix “@163.com”.