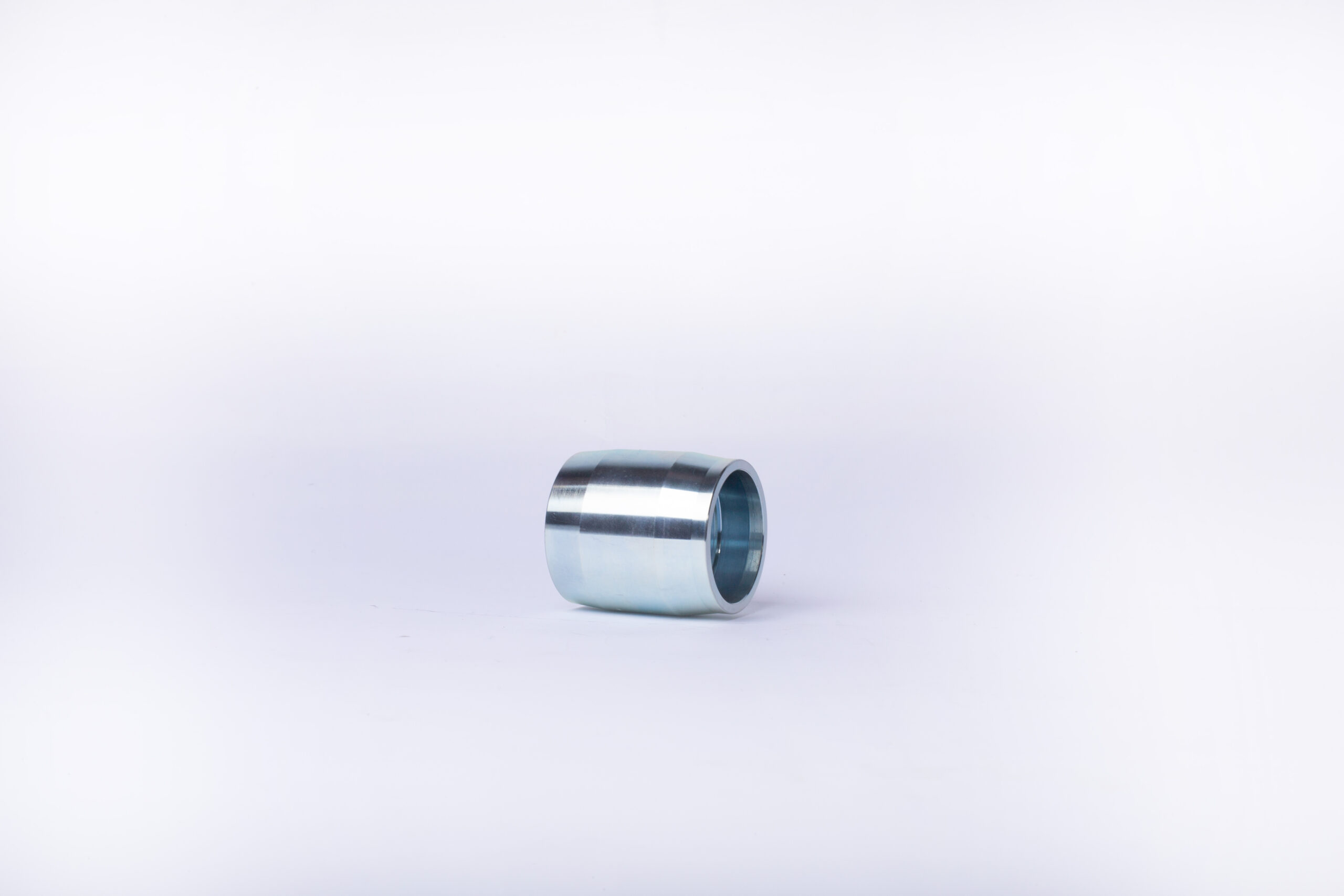

Product Name: Aluminum Forging

Product Type: Metal Forging

Material: Aluminum

Shape: Customized

Surface Treatment: Anodizing, Powder Coating, Spray Painting, Polishing

Production Process: Die Casting, Press Forging

Advantages:

1. High strength-to-weight ratio

2. Superior mechanical properties

3. Enhanced resistance to fatigue and wear

4. Tight dimensional tolerances

5. Cost-effective production

| Color | Silver |

|---|---|

| Material | Aluminum |

| MOQ | 1 Pcs |

| Sample | Available |

| Place of Origin | China |

Product Details

MINGYU Tech, with more than 20 years of experience in the extrusion process aluminum industry, is a trusted brand in the market. Our company specializes in custom extruded profiles and offers a variety of designs, surface finishes, and size options. We use advanced technology and equipment to produce high-precision extrusions that meet our customers’ specific requirements. Focusing on innovation, quality and customer satisfaction, MINGYU Tech has become a top player in the industry.

One of the key advantages of extrusion process aluminum is its lightweight nature. Aluminum is a lightweight metal, making it ideal for applications where weight reduction is important. It also has a high strength-to-weight ratio, making it suitable for structural components. Additionally, aluminum is corrosion-resistant, making it a durable choice for outdoor and industrial use.

Another benefit of extrusion process aluminum is its versatility. The process allows for the creation of intricate designs and complex shapes, giving designers and engineers the freedom to develop innovative and unique products. This versatility extends to the range of aluminum alloys that can be used in the extrusion process, each with its own unique properties and characteristics.

extrusion process aluminum also offers cost-effective production. It is a highly efficient process, which allows for large-scale production with minimal waste. This results in lower production costs, making extrusion process aluminum a more affordable option compared to other metal shaping methods. The use of lightweight and durable aluminum also contributes to cost savings in transportation and installation.

| Brand | MINGYU TechMINGYU Tech |

| Original | China |

| Capacity | 1225Ton/Month |

| Thickness | 0.3mm and above, or Customized |

| Length | 4-6.5Meter |

| Hardness | >=8HW |

| Color | Silver,White,Black,Grey,Bronze,Champagne,Wood and any as requested |

extrusion process aluminum FAQs Guide.

In this guide, we will provide you with all the information you need to know about our top-quality extrusion process aluminum and how they can benefit you and your projects. With extensive experience in the industry, our products are trusted by professionals and DIY enthusiasts alike. From industrial applications to home improvement projects, our extrusion process aluminum offer durability, versatility, and customization options to meet all your needs. Read on to discover more about our extrusion process aluminum products and why they should be your top choice.

1.Can aluminum extruded products be welded?

We focus on innovation and continuous improvement to maintain a competitive advantage.

Yes, aluminum extruded products can be welded. However, the welding process must be done carefully to ensure that the welded joint is strong and free of defects.

2.How does the use of extrusion process aluminum impact the weight of a product?

We should enjoy a good reputation in the industry, and we can increase the added value of the products of cooperative customers through technological innovation.

The use of aluminum extrusion can significantly reduce the weight of a product. Aluminum is a lightweight material, and when it is extruded into a specific shape, it can be used to create components that are much lighter than those made from other materials. This can be especially beneficial for products that need to be lightweight, such as aircraft or vehicles. Additionally, aluminum extrusion can be used to create complex shapes that would be difficult to achieve with other materials, further reducing the weight of the product.

3.What are the benefits of using extrusion process aluminum in manufacturing?

We attach importance to the innovation ability and team spirit of employees, have advanced R & D facilities and laboratories, and have a good quality management system.

1. Cost-Effective: Aluminum extrusion is a cost-effective manufacturing process that can produce complex shapes with minimal waste.

2. Versatility: Aluminum extrusion can be used to create a wide variety of shapes and sizes, making it a versatile manufacturing process.

3. Durability: Aluminum is a strong and durable material that can withstand harsh environments and is resistant to corrosion.

4. Lightweight: Aluminum is a lightweight material, making it ideal for applications where weight is a factor.

5. Recyclable: Aluminum is a recyclable material, making it an environmentally friendly choice for manufacturing.

4.How does the design of a product impact the extrusion process?

We should have a stable supply chain and logistics capabilities, and provide customers with high -quality, low -priced extrusion process aluminum products.

The design of a product can have a significant impact on the extrusion process. The shape, size, and complexity of the product will determine the type of extrusion process that is used, as well as the type of tooling and dies that are required. Additionally, the design of the product will determine the amount of material that is needed, the speed of the process, and the amount of time it takes to complete the extrusion process.

5.What is the weight-to-strength ratio of extrusion process aluminum compared to other materials?

We have a good reputation and image in the industry. The quality and price advantage of extrusion process aluminum products is an important factor in our hard overseas market.

The weight-to-strength ratio of aluminum extrusion is generally higher than other materials, such as steel and wood. Aluminum extrusion is lightweight and strong, making it an ideal choice for many applications. It is also corrosion-resistant and has a high thermal conductivity, making it suitable for use in a variety of industries.

6.How does extrusion process aluminum work?

We have a wide range of extrusion process aluminum customer groups and establishes long -term cooperative relationships with partners. The countries we provide services include $keyworrd{国家变量}.

Aluminum extrusion is a process in which aluminum is forced through a die of the desired cross-sectional profile. The aluminum is heated to a temperature of around 500°F (260°C) and then forced through the die by a ram. As the aluminum passes through the die, it takes on the shape of the die. The extruded aluminum is then cooled and cut to the desired length. The extruded aluminum can then be used for a variety of applications, such as window frames, door frames, and structural components.

7.What considerations should be taken for post-extrusion processing?

We are a professional extrusion process aluminum company dedicated to providing high quality products and services.

1. Cooling: After extrusion, the product must be cooled quickly to prevent warping or distortion.

2. Cutting: Depending on the product, it may need to be cut into smaller pieces or into specific shapes.

3. Finishing: Depending on the product, it may need to be sanded, polished, or painted.

4. Packaging: The product must be packaged properly to ensure it arrives safely to its destination.

5. Quality Control: Quality control measures should be taken to ensure the product meets the desired specifications.

8.How does the use of extrusion process aluminum impact the cost of a product?

We pay attention to the introduction and training of talents, scientifically regulate the management system, and focus on cultural construction and team cohesion.

The use of aluminum extrusion can have a significant impact on the cost of a product. Aluminum extrusion is a cost-effective way to produce complex shapes and sizes, and it can reduce the cost of production by eliminating the need for additional machining and fabrication. Additionally, aluminum extrusion can reduce the cost of materials, as it requires less material than other manufacturing processes. Finally, aluminum extrusion can reduce the cost of labor, as it is a relatively simple process that requires minimal setup and can be automated.

9.Can recycled aluminum be used in the extrusion process?

We actively participate in the extrusion process aluminum industry associations and organization activities. The corporate social responsibility performed well, and the focus of brand building and promotion

Yes, recycled aluminum can be used in the extrusion process. The recycled aluminum is melted down and then extruded into the desired shape. The recycled aluminum can be used in the same way as new aluminum, and it can be used to create a variety of products.

10.What is the maximum length and size that can be achieved through extrusion process aluminum?

We have rich industry experience and professional knowledge, and have strong competitiveness in the market.

The maximum length and size that can be achieved through aluminum extrusion depends on the type of aluminum alloy being used, the type of extrusion process, and the size of the extrusion press. Generally, aluminum extrusions can be made up to 12 feet in length and up to 8 inches in diameter.

11.What is the difference between hot and cold extrusion?

extrusion process aluminum is not a product only, but also can help you comes to money-making.

Hot extrusion is a process in which a metal is heated to a temperature above its recrystallization temperature and then forced through a die to form a desired shape. Cold extrusion is a process in which a metal is forced through a die at room temperature or slightly above. Cold extrusion is typically used for softer metals such as aluminum, copper, and brass, while hot extrusion is used for harder metals such as steel and titanium. Hot extrusion is more expensive and time consuming than cold extrusion, but it produces a stronger and more precise product.

12.What is the typical lead time for aluminum extruded products?

We are a new extrusion process aluminum manufacturer.

The typical lead time for aluminum extruded products can vary depending on the complexity of the product and the availability of raw materials. Generally, lead times range from 4-8 weeks.

13.How does the speed of the extrusion process affect the quality of the final product?

We enjoy high authority and influence in the industry and continue to innovate products and service models.

The speed of the extrusion process can have a significant impact on the quality of the final product. If the speed is too slow, the material may not be properly mixed and the product may not have the desired properties. If the speed is too fast, the material may be overworked and the product may be of poor quality. Additionally, the speed of the extrusion process can affect the surface finish of the product, as well as the dimensional accuracy.

Tag:aluminum extrusion fittings,aluminum mast extrusions,aluminum extrusion bending equipment

Product Inquiry

We will respond within 12 hours, please pay attention to the email “@163.com” or “@alumforge.com”.

Also, you can go to the Contact Page, which provides a more detailed form, if you have more inquiries for products or would like to obtain OEM service.

Our sales experts will respond within 24 hours, please pay attention to the email with the suffix “@163.com”.