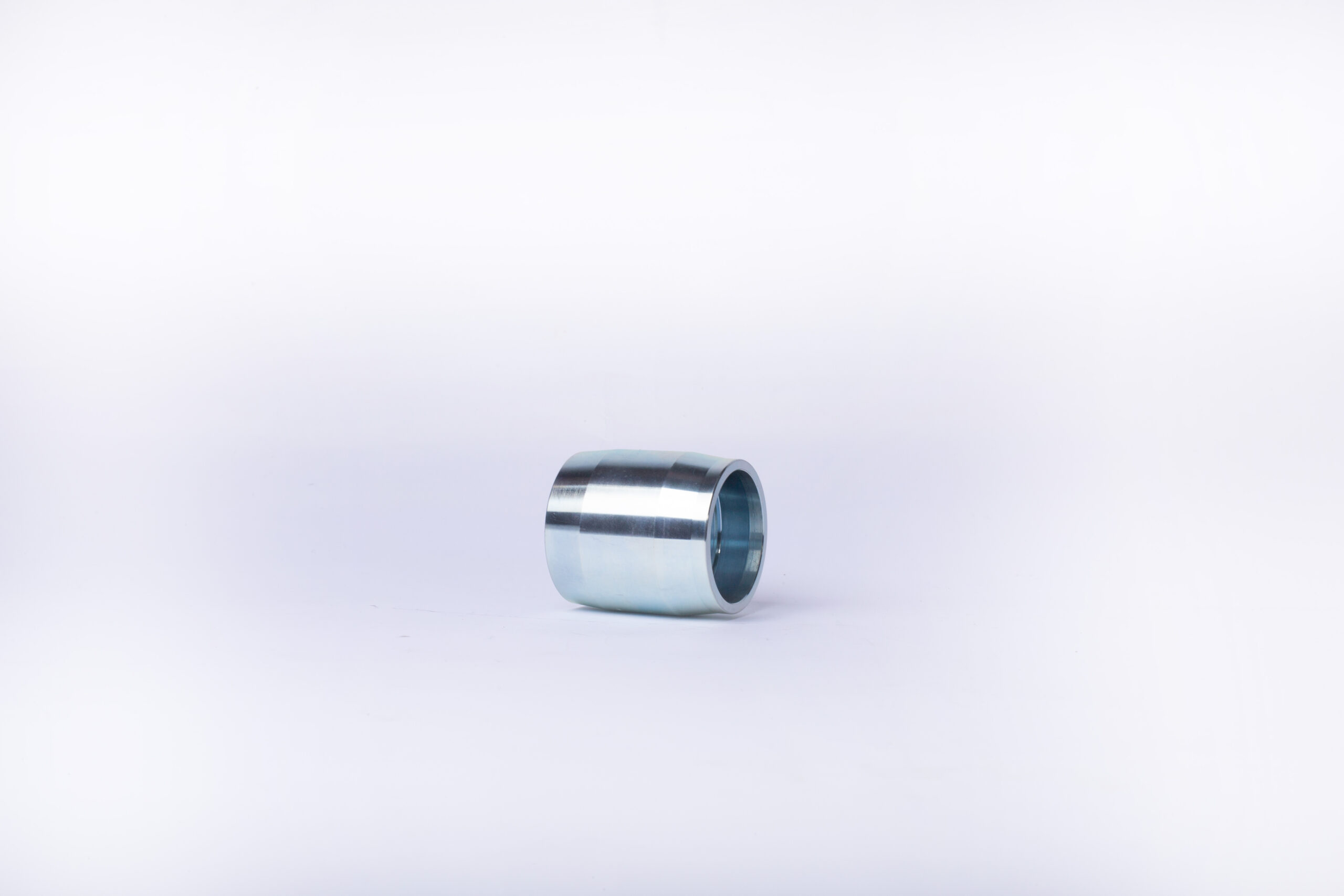

Product Name: Aluminum Forging

Product Type: Metal Forging

Material: Aluminum

Shape: Customized

Surface Treatment: Anodizing, Powder Coating, Spray Painting, Polishing

Production Process: Die Casting, Press Forging

Advantages:

1. High strength-to-weight ratio

2. Superior mechanical properties

3. Enhanced resistance to fatigue and wear

4. Tight dimensional tolerances

5. Cost-effective production

| Color | Silver |

|---|---|

| Material | Aluminum |

| MOQ | 1 Pcs |

| Sample | Available |

| Place of Origin | China |

Product Details

MINGYU Tech is a leading supplier of forged billet aluminum to the food and beverage industry. Our state-of-the-art facilities and advanced forging processes enable us to produce hygienic and corrosion-resistant forgings for food processing equipment, packaging machinery and other food-related applications. We work closely with our customers to provide customized solutions that meet their specific needs and comply with food safety regulations. Customer satisfaction and product quality are our top priorities.

The process of forged billet aluminum involves heating aluminum billets to a specific temperature and then using a high-pressure press to shape the metal into the desired form. The heat and pressure rearrange the molecular structure of the aluminum, making it stronger and more resistant to wear and tear. The result is a product with superior strength, ductility, and fatigue resistance compared to other manufacturing methods.

One of the main advantages of forged billet aluminum is its ability to produce parts with complex shapes and precise dimensions. This makes it an ideal method for creating lightweight yet strong components for applications that require tight tolerances and high-performance standards. forged billet aluminum is also known for its cost-effectiveness. As the process does not require multiple steps or extensive machining, it reduces the overall production time and minimizes material waste. Additionally, the high strength-to-weight ratio of aluminum allows for the production of lightweight products, which can lead to reduced fuel consumption and CO2 emissions in industries such as automotive manufacturing.

| Place of Origin | China |

| Material | Metal Aluminium Steel Copper Brass |

| Process | Forging+machining+HT+finish Machining |

| Surface treatment | Polishing |

| Application | Machinery Parts |

| Product name | forged billet aluminum |

| Certificate | TS16949/ISO9001 |

| Color | Customized Color |

| Quality Control | 100% Inspection |

| Lead Time | 13-31 Days |

| MOQ | 1 Piece |

| Supply Ability | 209856 Piece/Pieces per Month |

| Quantity (pieces) | > 569 |

| Lead time (days) | To be negotiated |

forged billet aluminum FAQs Guide.

Our company is dedicated to providing high-quality forged billet aluminum products to meet the needs of various industries. With advanced technology and skilled craftsmanship, we have become a leading manufacturer in the field of forged billet aluminum. Our products are widely used in aerospace, automotive, and construction industries, just to name a few. We take great pride in our products as they are not only durable and reliable, but also lightweight and eco-friendly. Through this introduction, we hope to showcase the versatility and excellence of our forged billet aluminum products. Thank you for choosing us as your trusted provider of top-notch forged billet aluminum products.

1.Can forged billet aluminums be welded or brazed?

Being one of the top forged billet aluminum manufacturers in China, We attach great importance to this detail.

Yes, aluminum forgings can be welded or brazed. However, it is important to note that aluminum is a difficult material to weld and requires special techniques and equipment. Brazing is often the preferred method for joining aluminum forgings, as it is less likely to cause warping or cracking.

2.What factors affect the strength and hardness of forged billet aluminums?

Our forged billet aluminum products have competitive and differentiated advantages, and actively promote digital transformation and innovation.

1. Alloy composition: The alloy composition of aluminum forgings affects the strength and hardness of the material. Different alloying elements can be added to aluminum to increase its strength and hardness.

2. Heat treatment: Heat treatment is an important factor in determining the strength and hardness of aluminum forgings. Different heat treatments can be used to increase the strength and hardness of aluminum forgings.

3. Grain size: The grain size of aluminum forgings affects the strength and hardness of the material. Smaller grain sizes can increase the strength and hardness of aluminum forgings.

4. Stress relief: Stress relief is an important factor in determining the strength and hardness of aluminum forgings. Stress relief can be used to reduce internal stresses in the material, which can increase the strength and hardness of aluminum forgings.

5. Surface finish: The surface finish of aluminum forgings affects the strength and hardness of the material. A smoother surface finish can increase the strength and hardness of aluminum forgings.

3.About forged billet aluminum R&D capabilities

Aluminum forging R&D capabilities are highly advanced and have been developed over many years. Companies that specialize in aluminum forging have invested heavily in research and development to create new and improved processes and products. This has enabled them to produce high-quality aluminum components that are lighter, stronger, and more cost-effective than ever before. Aluminum forging R&D capabilities include the development of new alloys, improved forging techniques, and the use of advanced computer-aided design and manufacturing (CAD/CAM) systems. These capabilities have enabled aluminum forging companies to produce components that meet the highest standards of quality and performance.

4.What are the different types of forged billet aluminum?

We have flexible production capacity. Whether you are large orders or small orders, you can produce and release goods in a timely manner to meet customer needs.

1. Closed Die Forging: This type of forging involves the use of two dies that are closed together to form a shape. The dies are usually made of steel and the aluminum is heated and then placed between the dies. The dies are then closed and the aluminum is forced into the desired shape.

2. Open Die Forging: This type of forging involves the use of a single die that is open at the top. The aluminum is heated and then placed in the die. The die is then closed and the aluminum is forced into the desired shape.

3. Roll Forging: This type of forging involves the use of two rolls that are used to shape the aluminum. The aluminum is heated and then placed between the rolls. The rolls are then rotated and the aluminum is forced into the desired shape.

4. Impact Forging: This type of forging involves the use of a hammer or other tool to shape the aluminum. The aluminum is heated and then placed on an anvil. The hammer or other tool is then used to shape the aluminum into the desired shape.

5.What industries commonly use forged billet aluminums?

We attach importance to the innovation ability and team spirit of employees, have advanced R & D facilities and laboratories, and have a good quality management system.

Aluminum forgings are commonly used in the automotive, aerospace, defense, and marine industries. They are also used in the construction, medical, and sporting goods industries.

6.How do environmental factors, such as temperature and humidity, affect the forged billet aluminum process?

We focus on teamwork and communication to achieve common goals, We attach great importance to this detail.

Temperature and humidity can have a significant impact on the aluminum forging process. High temperatures can cause the aluminum to become too soft and malleable, making it difficult to form into the desired shape. Low temperatures can cause the aluminum to become too brittle and crack during the forging process. High humidity can cause the aluminum to become sticky and difficult to work with, while low humidity can cause the aluminum to become too dry and brittle. Additionally, high temperatures and humidity can cause the aluminum to corrode more quickly, leading to a shorter lifespan for the forged product.

7.How does the forging process affect the microstructure of aluminum?

Our company has many years of forged billet aluminum experience and expertise.

The forging process can affect the microstructure of aluminum in several ways. During the forging process, the aluminum is subjected to high temperatures and pressures, which can cause the grain structure of the aluminum to become finer and more uniform. This can improve the strength and ductility of the aluminum, as well as its fatigue resistance. Additionally, the forging process can also cause the aluminum to become more homogenous, which can improve its corrosion resistance.

8.Are there any limitations to the size or complexity of products that can be forged from aluminum?

We adhere to the principle of integrity and transparency, and establish long -term relationships with partners, and we attach great importance to this detail.

Yes, there are limitations to the size and complexity of products that can be forged from aluminum. Aluminum is a relatively soft metal, so it is not suitable for forging large or complex parts. Additionally, aluminum has a low melting point, so it is not suitable for forging parts that require high temperatures.

9.Can secondary operations, such as machining or surface coating, be performed on forged billet aluminums?

Yes, secondary operations such as machining and surface coating can be performed on aluminum forgings. Machining can be used to create complex shapes and features, while surface coating can be used to improve the corrosion resistance and aesthetic appearance of the part.

10.About forged billet aluminum MOQ

The minimum order quantity (MOQ) for aluminum forging depends on the size and complexity of the part being forged. Generally, the MOQ for aluminum forging is between 500 and 1000 pieces. However, some aluminum forging companies may be willing to accept orders for smaller quantities.

11.About the scale of forged billet aluminum factory

The size of an aluminum forging factory depends on the type of products it produces and the size of the orders it receives. Some aluminum forging factories may be small, producing only a few parts at a time, while others may be large, producing thousands of parts per day. The size of the factory also depends on the type of equipment used, the number of employees, and the amount of space available.

12.About forged billet aluminum technology

Aluminum forging is a metalworking process in which metal is heated and then shaped into a desired shape by applying pressure. It is a process that is used to create parts with improved strength and durability. Aluminum forging is used in a variety of industries, including aerospace, automotive, and medical. The process is used to create parts with complex shapes and tight tolerances. Aluminum forging is a cost-effective way to produce parts with superior strength and durability. The process is also used to create parts with improved fatigue resistance and corrosion resistance.

13.Are there any unique thermal or electrical properties of forged billet aluminums?

We maintain a stable growth through reasonable capital operations, focus on industry development trends and cutting -edge technologies, and focus on product quality and safety performance.

Yes, aluminum forgings have unique thermal and electrical properties. Aluminum is a good conductor of electricity and heat, and its thermal conductivity is higher than that of steel. Aluminum also has a high strength-to-weight ratio, making it an ideal material for forging. Additionally, aluminum forgings are corrosion-resistant and have excellent fatigue strength.

14.What are the most common applications of forged billet aluminum?

We enjoy high authority and influence in the industry and continue to innovate products and service models.

1. Automotive components: Aluminum forging is used to create a variety of automotive components, such as engine blocks, cylinder heads, transmission cases, and suspension components.

2. Aerospace components: Aluminum forging is used to create components for aircraft, such as landing gear, wing spars, and fuselage frames.

3. Industrial components: Aluminum forging is used to create components for industrial machinery, such as pumps, valves, and gears.

4. Sporting goods: Aluminum forging is used to create components for sporting goods, such as bicycle frames, golf clubs, and baseball bats.

5. Hand tools: Aluminum forging is used to create components for hand tools, such as hammers, wrenches, and screwdrivers.

15.About forged billet aluminum raw material procurement system

Aluminum forging raw material procurement system is a computerized system designed to streamline the process of procuring raw materials for aluminum forging. The system is designed to provide a comprehensive view of the entire procurement process, from the initial request for materials to the final delivery of the materials. The system can be used to track the status of orders, monitor inventory levels, and generate reports on the performance of the procurement process. The system also provides a platform for communication between suppliers and buyers, allowing for efficient and timely communication. The system can also be used to automate the process of ordering and tracking materials, reducing the amount of manual labor required.

16.About forged billet aluminum production capacity

Aluminum forging production capacity is determined by the size and complexity of the parts being produced, the type of forging process used, and the number of machines available. Generally, the larger the part, the more machines and time are required to produce it. The complexity of the part also affects the production capacity, as more complex parts require more time and machines to produce. Additionally, the type of forging process used can affect the production capacity, as some processes are more efficient than others.

Tag:china aluminum forging factory,quality aluminum forge fire video,forged aluminum blanks

Product Inquiry

We will respond within 12 hours, please pay attention to the email “@163.com” or “@alumforge.com”.

Also, you can go to the Contact Page, which provides a more detailed form, if you have more inquiries for products or would like to obtain OEM service.

Our sales experts will respond within 24 hours, please pay attention to the email with the suffix “@163.com”.