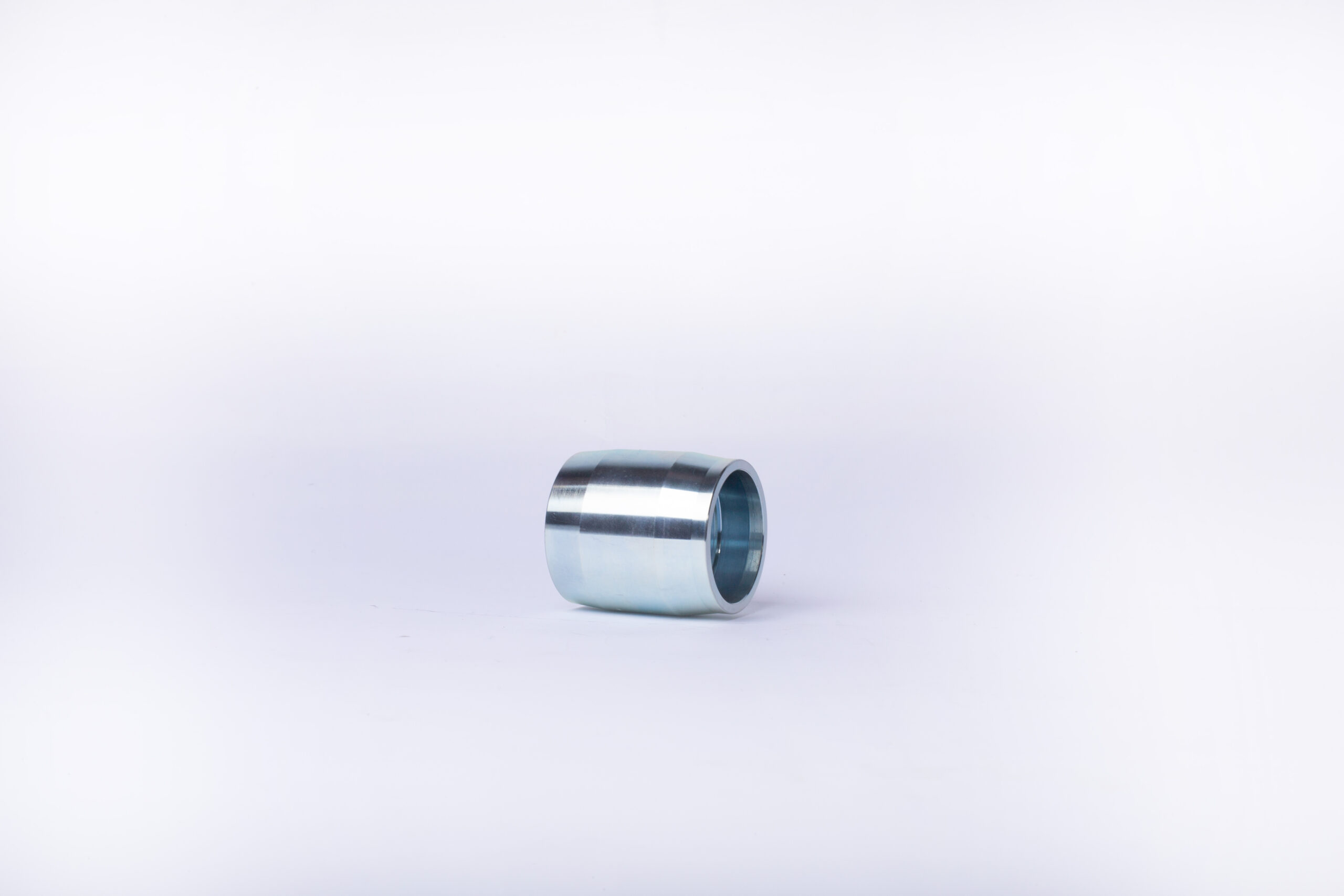

Product Name: Aluminum Forging

Product Type: Metal Forging

Material: Aluminum

Shape: Customized

Surface Treatment: Anodizing, Powder Coating, Spray Painting, Polishing

Production Process: Die Casting, Press Forging

Advantages:

1. High strength-to-weight ratio

2. Superior mechanical properties

3. Enhanced resistance to fatigue and wear

4. Tight dimensional tolerances

5. Cost-effective production

| Color | Silver |

|---|---|

| Material | Aluminum |

| MOQ | 1 Pcs |

| Sample | Available |

| Place of Origin | China |

Product Details

MINGYU Tech is a leading supplier of general aluminum forge to the food and beverage industry. Our state-of-the-art facilities and advanced forging processes enable us to produce hygienic and corrosion-resistant forgings for food processing equipment, packaging machinery and other food-related applications. We work closely with our customers to provide customized solutions that meet their specific needs and comply with food safety regulations. Customer satisfaction and product quality are our top priorities.

The first step in the general aluminum forge process is to select the appropriate grade of aluminum for the desired product. Different aluminum alloys have varying chemical compositions and properties, making them suitable for different applications. Once the aluminum has been chosen, it is heated in a furnace to a temperature between 700-800 degrees Fahrenheit. This temperature is critical, as it allows the aluminum to become malleable without melting.

Next, the heated aluminum is placed into a forging machine, where it is subjected to intense pressure. This pressure changes the shape of the aluminum, creating the desired product. The process is repeated multiple times, with the aluminum being reheated and re-forged until it reaches its final shape and size. This method of shaping allows for precise control over the dimensions and specifications of the product.

general aluminum forges are known for their high strength-to-weight ratio, making them ideal for applications in the aerospace, automotive, and defense industries. They are also highly resistant to corrosion and have excellent thermal and electrical conductivity, making them suitable for use in electrical components. The precision and durability of general aluminum forges make them a popular choice for critical components such as aircraft parts, automobile engine components, and industrial machinery.

| Place of Origin | China |

| Material | Metal Aluminium Steel Copper Brass |

| Process | Forging+machining+HT+finish Machining |

| Surface treatment | Polishing |

| Application | Machinery Parts |

| Product name | general aluminum forge |

| Certificate | TS16949/ISO9001 |

| Color | Customized Color |

| Quality Control | 100% Inspection |

| Lead Time | 10-35 Days |

| MOQ | 1 Piece |

| Supply Ability | 184663 Piece/Pieces per Month |

| Quantity (pieces) | > 564 |

| Lead time (days) | To be negotiated |

general aluminum forge FAQs Guide.

Our company is dedicated to providing high-quality general aluminum forge products to meet the needs of various industries. With advanced technology and skilled craftsmanship, we have become a leading manufacturer in the field of general aluminum forge. Our products are widely used in aerospace, automotive, and construction industries, just to name a few. We take great pride in our products as they are not only durable and reliable, but also lightweight and eco-friendly. Through this introduction, we hope to showcase the versatility and excellence of our general aluminum forge products. Thank you for choosing us as your trusted provider of top-notch general aluminum forge products.

1.What are the key differences between open die and closed die general aluminum forge?

We continuously upgrade our skills and knowledge to adapt to changing general aluminum forge market needs.

Open die forging is a process in which a hammer or press is used to shape a piece of metal between two flat dies without completely enclosing it. This process is used to create large, custom-shaped parts. Closed die forging is a process in which a hammer or press is used to shape a piece of metal between two dies that completely enclose the metal. This process is used to create smaller, more precise parts with tighter tolerances.

2.How does heat treatment affect the strength and durability of general aluminum forges?

We maintain a certain amount of R&D investment every year and continuously improve operational efficiency to provide better services to our cooperative customers.

Heat treatment can significantly improve the strength and durability of aluminum forgings. Heat treatment can increase the strength of aluminum by increasing the hardness of the material, which can help to reduce wear and tear. Heat treatment can also improve the fatigue strength of aluminum, which can help to increase the life of the part. Heat treatment can also improve the corrosion resistance of aluminum, which can help to increase the durability of the part.

3.What safety measures should be taken during the handling and transportation of hot general aluminum forges?

Our mission is to provide customers with the best solutions for general aluminum forge.

1. Wear protective clothing, such as heat-resistant gloves, long-sleeved shirts, and safety glasses.

2. Use appropriate lifting equipment, such as slings, chains, and hooks, to move the hot aluminum forgings.

3. Secure the hot aluminum forgings with straps or chains to prevent them from shifting during transportation.

4. Ensure that the hot aluminum forgings are properly insulated to prevent heat loss.

5. Monitor the temperature of the hot aluminum forgings during transportation to ensure that they do not exceed the maximum temperature limit.

6. Use a fire extinguisher in case of an emergency.

7. Ensure that the hot aluminum forgings are transported in a well-ventilated area.

8. Avoid contact with combustible materials while handling and transporting the hot aluminum forgings.

4.What is the typical lifespan of an general aluminum forge compared to other metal parts?

The typical lifespan of an aluminum forging is typically longer than other metal parts due to its superior strength and corrosion resistance. Aluminum forgings can last up to three times longer than other metal parts, depending on the application.

5.What are the quality control measures taken during general aluminum forge?

I have a comprehensive after -sales service system, which can pay attention to market trends in time and adjust our strategy in a timely manner.

1. Visual Inspection: Visual inspection is one of the most important quality control measures taken during aluminum forging. This involves inspecting the forged parts for any visible defects such as cracks, porosity, or other surface imperfections.

2. Dimensional Inspection: Dimensional inspection is another important quality control measure taken during aluminum forging. This involves measuring the dimensions of the forged parts to ensure that they meet the required specifications.

3. Chemical Analysis: Chemical analysis is also an important quality control measure taken during aluminum forging. This involves testing the chemical composition of the forged parts to ensure that they meet the required specifications.

4. Non-Destructive Testing: Non-destructive testing is also an important quality control measure taken during aluminum forging. This involves testing the forged parts for any internal defects such as cracks, porosity, or other internal imperfections.

5. Stress Testing: Stress testing is also an important quality control measure taken during aluminum forging. This involves testing the forged parts for any stress-related defects such as cracks, porosity, or other stress-related imperfections.

6.Are there any surface treatment options for general aluminum forges?

Our general aluminum forge products undergo strict quality control to ensure customer satisfaction.

Yes, there are several surface treatment options for aluminum forgings, including anodizing, powder coating, painting, and plating. Anodizing is a process that creates a protective oxide layer on the surface of the aluminum, while powder coating and painting are used to add color and texture to the surface. Plating is used to add a layer of metal to the surface of the aluminum, such as chrome or nickel.

7.About general aluminum forge overseas warehouse

Aluminum forging overseas warehouses are warehouses located in foreign countries that specialize in the storage and distribution of aluminum forgings. These warehouses are typically located in countries with a strong aluminum forging industry, such as China, India, and the United States. They provide a convenient and cost-effective way for companies to store and distribute their aluminum forgings, as well as to access the global market. The warehouses are typically equipped with the latest technology and equipment to ensure the highest quality of aluminum forgings.

8.What are the properties of aluminum that make it suitable for forging?

We have the leading technology and innovation capabilities, and attach importance to employee training and development, and provide promotion opportunities.

1. Aluminum is lightweight and strong, making it ideal for forging.

2. Aluminum has a low melting point, making it easy to shape and form.

3. Aluminum is corrosion-resistant, making it suitable for outdoor applications.

4. Aluminum is malleable and ductile, making it easy to work with.

5. Aluminum is a good conductor of heat and electricity, making it suitable for electrical components.

6. Aluminum is non-magnetic, making it suitable for use in sensitive electronic equipment.

7. Aluminum is relatively inexpensive, making it a cost-effective choice for many applications.

9.What are the material testing methods used for evaluating general aluminum forges?

1. Visual Inspection: This is the most basic form of testing and involves examining the surface of the aluminum forging for any signs of defects or irregularities.

2. Ultrasonic Testing: This method uses high-frequency sound waves to detect any internal flaws or defects in the aluminum forging.

3. Magnetic Particle Testing: This method uses a magnetic field to detect any surface or subsurface flaws in the aluminum forging.

4. Radiographic Testing: This method uses X-rays to detect any internal flaws or defects in the aluminum forging.

5. Hardness Testing: This method uses a hardness tester to measure the hardness of the aluminum forging.

6. Chemical Analysis: This method involves analyzing the chemical composition of the aluminum forging to ensure it meets the required specifications.

10.How are defects identified and corrected during the general aluminum forge process?

Our products & services cover a wide range of areas and meet the needs of different fields.

Defects in aluminum forging can be identified and corrected through a variety of methods. Visual inspection is the most common method used to identify defects. This involves looking for surface irregularities, such as cracks, porosity, or other surface defects. Ultrasonic testing is also used to detect internal defects, such as voids, inclusions, or cracks. X-ray and radiographic testing can also be used to detect internal defects. Once a defect is identified, it can be corrected by reworking the part, using a different forging process, or by using a different material.

11.About general aluminum forge inventory

Aluminum forging inventory is a collection of aluminum parts that have been forged into a specific shape or size. This inventory is typically used in the manufacturing of parts for various industries, such as automotive, aerospace, and medical. Aluminum forging is a process that involves heating and shaping aluminum into a desired shape or size. This process is often used to create parts that are stronger and more durable than those made from other materials. Aluminum forging inventory can include a variety of shapes and sizes, including rods, bars, tubes, and plates.

12.What are the different heat treatment processes used for general aluminum forges?

We have a first -class management team, and we pay attention to teamwork to achieve common goals.

1. Solution Heat Treatment: This process involves heating the aluminum forging to a temperature above its solidus temperature and then rapidly cooling it. This process is used to improve the strength and hardness of the aluminum forging.

2. Aging: This process involves heating the aluminum forging to a temperature below its solidus temperature and then allowing it to cool slowly. This process is used to improve the strength and hardness of the aluminum forging.

3. Annealing: This process involves heating the aluminum forging to a temperature above its solidus temperature and then allowing it to cool slowly. This process is used to improve the ductility and machinability of the aluminum forging.

4. Stress Relieving: This process involves heating the aluminum forging to a temperature below its solidus temperature and then allowing it to cool slowly. This process is used to reduce internal stresses in the aluminum forging.

5. Normalizing: This process involves heating the aluminum forging to a temperature above its solidus temperature and then allowing it to cool in air. This process is used to improve the strength and hardness of the aluminum forging.

13.Are there any differences in the mechanical properties of forged and cast aluminum?

We pay attention to the transformation of intellectual property protection and innovation achievements. Your OEM or ODM order design we have a complete confidentiality system.

Yes, there are differences in the mechanical properties of forged and cast aluminum. Forged aluminum is typically stronger and more ductile than cast aluminum, due to the forging process which increases the grain size and improves the mechanical properties. Forged aluminum also has a higher yield strength and tensile strength than cast aluminum. Cast aluminum is typically softer and more brittle than forged aluminum, and has a lower yield strength and tensile strength.

14.How is general aluminum forge different from other metal forging processes?

We continue to invest in research and development and continue to launch innovative products.

Aluminum forging is different from other metal forging processes in that it requires a different set of tools and techniques. Aluminum is a softer metal than other metals, so it requires a different set of tools and techniques to shape it. Aluminum forging also requires a lower temperature than other metals, so it is more energy efficient. Additionally, aluminum forging is more cost effective than other metal forging processes due to its lower melting point.

Tag:aluminum forging materials,aluminum drop forging,aluminum 7075-t73 forging,aluminum hot forging

Product Inquiry

We will respond within 12 hours, please pay attention to the email “@163.com” or “@alumforge.com”.

Also, you can go to the Contact Page, which provides a more detailed form, if you have more inquiries for products or would like to obtain OEM service.

Our sales experts will respond within 24 hours, please pay attention to the email with the suffix “@163.com”.