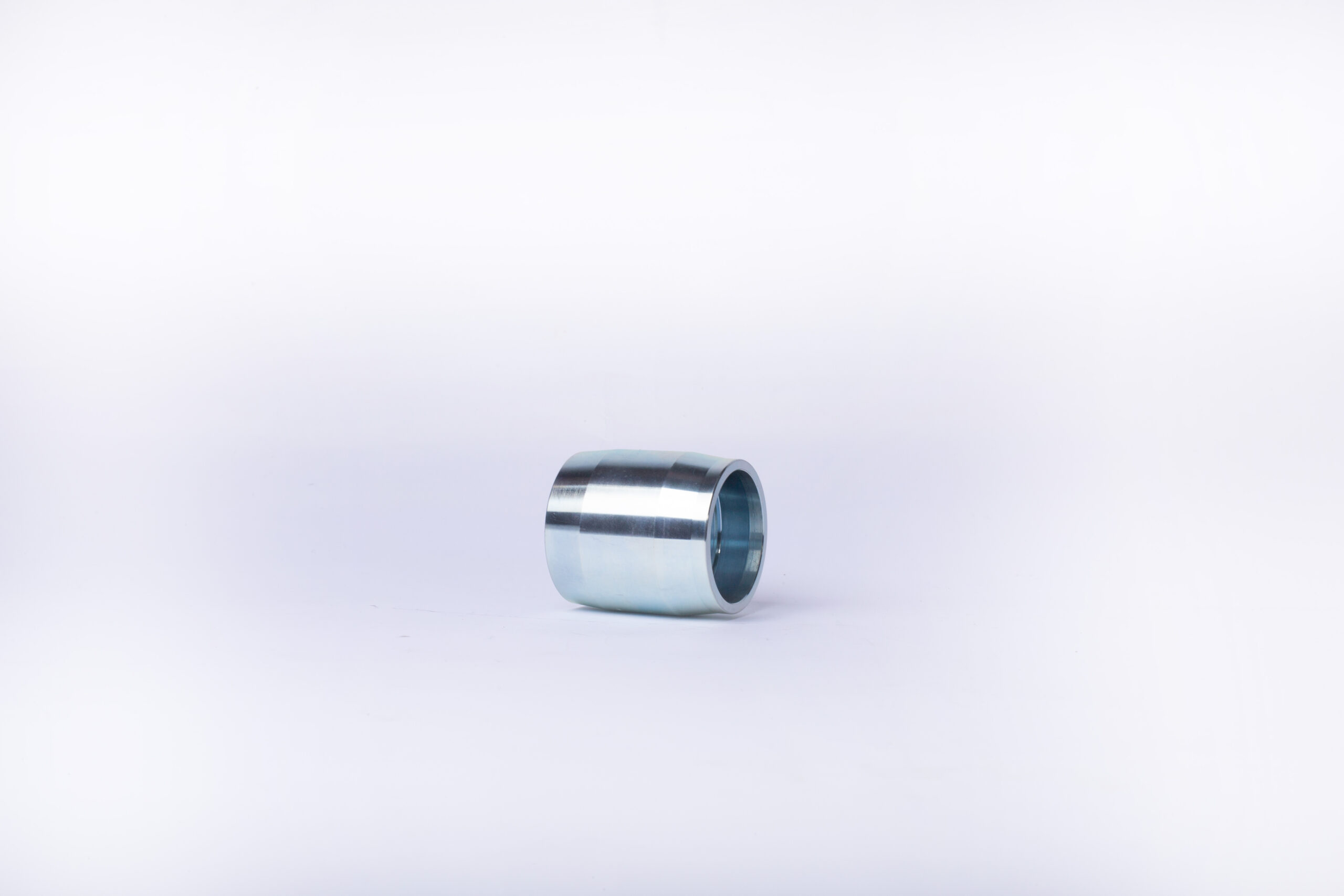

Product Name: Aluminum Forging

Product Type: Metal Forging

Material: Aluminum

Shape: Customized

Surface Treatment: Anodizing, Powder Coating, Spray Painting, Polishing

Production Process: Die Casting, Press Forging

Advantages:

1. High strength-to-weight ratio

2. Superior mechanical properties

3. Enhanced resistance to fatigue and wear

4. Tight dimensional tolerances

5. Cost-effective production

| Color | Silver |

|---|---|

| Material | Aluminum |

| MOQ | 1 Pcs |

| Sample | Available |

| Place of Origin | China |

Product Details

MINGYU Tech is a leading manufacturer of agricultural gt forged aluminum bike. Our state-of-the-art facilities enable us to produce strong, lightweight and corrosion-resistant forgings for a variety of agricultural equipment and machinery. With over 20 years of experience, we have a deep understanding of the unique challenges in agriculture and can provide customized solutions to meet our customers’ requirements. We are committed to providing our customers with the highest quality products and excellent customer service.

gt forged aluminum bike is a manufacturing process that involves applying extreme pressure to reshape and form aluminum alloys into desired industrial or commercial products. It is a cost-effective and efficient method for producing high-strength, lightweight, and durable aluminum components for various applications.

The process of gt forged aluminum bike begins with melting and pouring the aluminum alloy into a die or mold. The heated alloy is then pressed and forced into its desired shape using a hammer or press under high pressure. This compressive force rearranges the aluminum molecules, resulting in a strong and dense metal with enhanced mechanical properties. The use of gt forged aluminum bike can produce a wide range of products, including automotive components, aerospace parts, construction equipment, and household tools. Its versatility allows for the creation of complex shapes and designs that are not feasible with other manufacturing techniques.

| Place of Origin | China |

| Material | Metal Aluminium Steel Copper Brass |

| Process | Forging+machining+HT+finish Machining |

| Surface treatment | Polishing |

| Application | Machinery Parts |

| Product name | gt forged aluminum bike |

| Certificate | TS16949/ISO9001 |

| Color | Customized Color |

| Quality Control | 100% Inspection |

| Lead Time | 16-32 Days |

| MOQ | 1 Piece |

| Supply Ability | 202349 Piece/Pieces per Month |

| Quantity (pieces) | > 470 |

| Lead time (days) | To be negotiated |

gt forged aluminum bike FAQs Guide.

Our company is dedicated to providing high-quality gt forged aluminum bike products to meet the needs of various industries. With advanced technology and skilled craftsmanship, we have become a leading manufacturer in the field of gt forged aluminum bike. Our products are widely used in aerospace, automotive, and construction industries, just to name a few. We take great pride in our products as they are not only durable and reliable, but also lightweight and eco-friendly. Through this introduction, we hope to showcase the versatility and excellence of our gt forged aluminum bike products. Thank you for choosing us as your trusted provider of top-notch gt forged aluminum bike products.

1.About the development history of gt forged aluminum bike factory

Aluminum forging is a process of forming and shaping metal by hammering, pressing, or rolling. It has been used since ancient times to create tools, weapons, and other objects. The earliest known use of aluminum forging dates back to the Bronze Age, when it was used to create weapons and tools. In the 19th century, aluminum forging became more widely used in the production of industrial components, such as engine parts and aircraft components. Today, aluminum forging is used in a variety of industries, including automotive, aerospace, and medical. Aluminum forging factories have been around since the early 1900s, when they were used to produce parts for the automotive industry. Over the years, these factories have evolved to become more efficient and technologically advanced, allowing them to produce parts with greater precision and accuracy.

2.What are the different types of gt forged aluminum bike?

We have flexible production capacity. Whether you are large orders or small orders, you can produce and release goods in a timely manner to meet customer needs.

1. Closed Die Forging: This type of forging involves the use of two dies that are closed together to form a shape. The dies are usually made of steel and the aluminum is heated and then placed between the dies. The dies are then closed and the aluminum is forced into the desired shape.

2. Open Die Forging: This type of forging involves the use of a single die that is open at the top. The aluminum is heated and then placed in the die. The die is then closed and the aluminum is forced into the desired shape.

3. Roll Forging: This type of forging involves the use of two rolls that are used to shape the aluminum. The aluminum is heated and then placed between the rolls. The rolls are then rotated and the aluminum is forced into the desired shape.

4. Impact Forging: This type of forging involves the use of a hammer or other tool to shape the aluminum. The aluminum is heated and then placed on an anvil. The hammer or other tool is then used to shape the aluminum into the desired shape.

3.Are there any surface treatment options for gt forged aluminum bikes?

Our gt forged aluminum bike products undergo strict quality control to ensure customer satisfaction.

Yes, there are several surface treatment options for aluminum forgings, including anodizing, powder coating, painting, and plating. Anodizing is a process that creates a protective oxide layer on the surface of the aluminum, while powder coating and painting are used to add color and texture to the surface. Plating is used to add a layer of metal to the surface of the aluminum, such as chrome or nickel.

4.How does the choice of die affect the final product in gt forged aluminum bike?

We have established a good reputation and reliable partnerships within the gt forged aluminum bike industry.

The choice of die affects the final product in aluminum forging in several ways. The die design determines the shape of the final product, as well as the surface finish and dimensional accuracy. The die material also affects the final product, as different materials have different properties that can affect the strength and durability of the final product. Additionally, the die size and shape can affect the amount of force required to form the aluminum, as well as the amount of time it takes to complete the forging process.

5.What are the quality control measures taken during gt forged aluminum bike?

I have a comprehensive after -sales service system, which can pay attention to market trends in time and adjust our strategy in a timely manner.

1. Visual Inspection: Visual inspection is one of the most important quality control measures taken during aluminum forging. This involves inspecting the forged parts for any visible defects such as cracks, porosity, or other surface imperfections.

2. Dimensional Inspection: Dimensional inspection is another important quality control measure taken during aluminum forging. This involves measuring the dimensions of the forged parts to ensure that they meet the required specifications.

3. Chemical Analysis: Chemical analysis is also an important quality control measure taken during aluminum forging. This involves testing the chemical composition of the forged parts to ensure that they meet the required specifications.

4. Non-Destructive Testing: Non-destructive testing is also an important quality control measure taken during aluminum forging. This involves testing the forged parts for any internal defects such as cracks, porosity, or other internal imperfections.

5. Stress Testing: Stress testing is also an important quality control measure taken during aluminum forging. This involves testing the forged parts for any stress-related defects such as cracks, porosity, or other stress-related imperfections.

6.How does heat treatment affect the strength and durability of gt forged aluminum bikes?

We maintain a certain amount of R&D investment every year and continuously improve operational efficiency to provide better services to our cooperative customers.

Heat treatment can significantly improve the strength and durability of aluminum forgings. Heat treatment can increase the strength of aluminum by increasing the hardness of the material, which can help to reduce wear and tear. Heat treatment can also improve the fatigue strength of aluminum, which can help to increase the life of the part. Heat treatment can also improve the corrosion resistance of aluminum, which can help to increase the durability of the part.

7.How does the surface finish affect the performance of gt forged aluminum bikes?

The surface finish of aluminum forgings can have a significant impact on the performance of the part. A smooth, uniform surface finish can reduce friction and wear, improve fatigue strength, and reduce the risk of corrosion. A rough surface finish can increase friction and wear, reduce fatigue strength, and increase the risk of corrosion.

8.About gt forged aluminum bike raw material procurement system

Aluminum forging raw material procurement system is a computerized system designed to streamline the process of procuring raw materials for aluminum forging. The system is designed to provide a comprehensive view of the entire procurement process, from the initial request for materials to the final delivery of the materials. The system can be used to track the status of orders, monitor inventory levels, and generate reports on the performance of the procurement process. The system also provides a platform for communication between suppliers and buyers, allowing for efficient and timely communication. The system can also be used to automate the process of ordering and tracking materials, reducing the amount of manual labor required.

9.Are there any special requirements for handling or storing gt forged aluminum bikes?

We are centered on customers and always pay attention to customers’ needs for gt forged aluminum bike products.

Yes, aluminum forgings should be stored in a dry, cool, and well-ventilated area away from direct sunlight and other sources of heat. Additionally, aluminum forgings should be handled with care to avoid damage and should be stored on a flat surface to prevent warping.

10.About gt forged aluminum bike overseas warehouse

Aluminum forging overseas warehouses are warehouses located in foreign countries that specialize in the storage and distribution of aluminum forgings. These warehouses are typically located in countries with a strong aluminum forging industry, such as China, India, and the United States. They provide a convenient and cost-effective way for companies to store and distribute their aluminum forgings, as well as to access the global market. The warehouses are typically equipped with the latest technology and equipment to ensure the highest quality of aluminum forgings.

11.About gt forged aluminum bike production management system

The Aluminum Forging Production Management System is a comprehensive software solution designed to help aluminum forging companies manage their production processes. It provides a comprehensive set of tools to help manage the entire production process from order entry to delivery. The system includes features such as order tracking, inventory management, scheduling, quality control, and cost analysis. It also provides reporting and analytics to help companies make informed decisions about their production processes. The system is designed to be user-friendly and can be customized to meet the specific needs of each company.

12.What is the role of lubrication in gt forged aluminum bike?

We adhere to the principle of quality first and have a complete production quality management system and quality inspection process.

Lubrication plays an important role in aluminum forging. It helps reduce friction between the metal and the die, which can reduce wear and tear on the die and help to improve the quality of the finished product. It also helps to reduce the amount of heat generated during the forging process, which can help to prevent the aluminum from becoming too hot and causing damage to the die. Finally, lubrication can help to reduce the amount of force required to form the aluminum, which can help to reduce the amount of energy used in the process.

13.Can secondary operations, such as machining or surface coating, be performed on gt forged aluminum bikes?

Yes, secondary operations such as machining and surface coating can be performed on aluminum forgings. Machining can be used to create complex shapes and features, while surface coating can be used to improve the corrosion resistance and aesthetic appearance of the part.

14.What is the typical lifespan of an gt forged aluminum bike compared to other metal parts?

The typical lifespan of an aluminum forging is typically longer than other metal parts due to its superior strength and corrosion resistance. Aluminum forgings can last up to three times longer than other metal parts, depending on the application.

Tag:china aluminum forging manufacturers,forged 6061 aluminum 52t,polished forged aluminum wheels,brass aluminum forge mark

Product Inquiry

We will respond within 12 hours, please pay attention to the email “@163.com” or “@alumforge.com”.

Also, you can go to the Contact Page, which provides a more detailed form, if you have more inquiries for products or would like to obtain OEM service.

Our sales experts will respond within 24 hours, please pay attention to the email with the suffix “@163.com”.