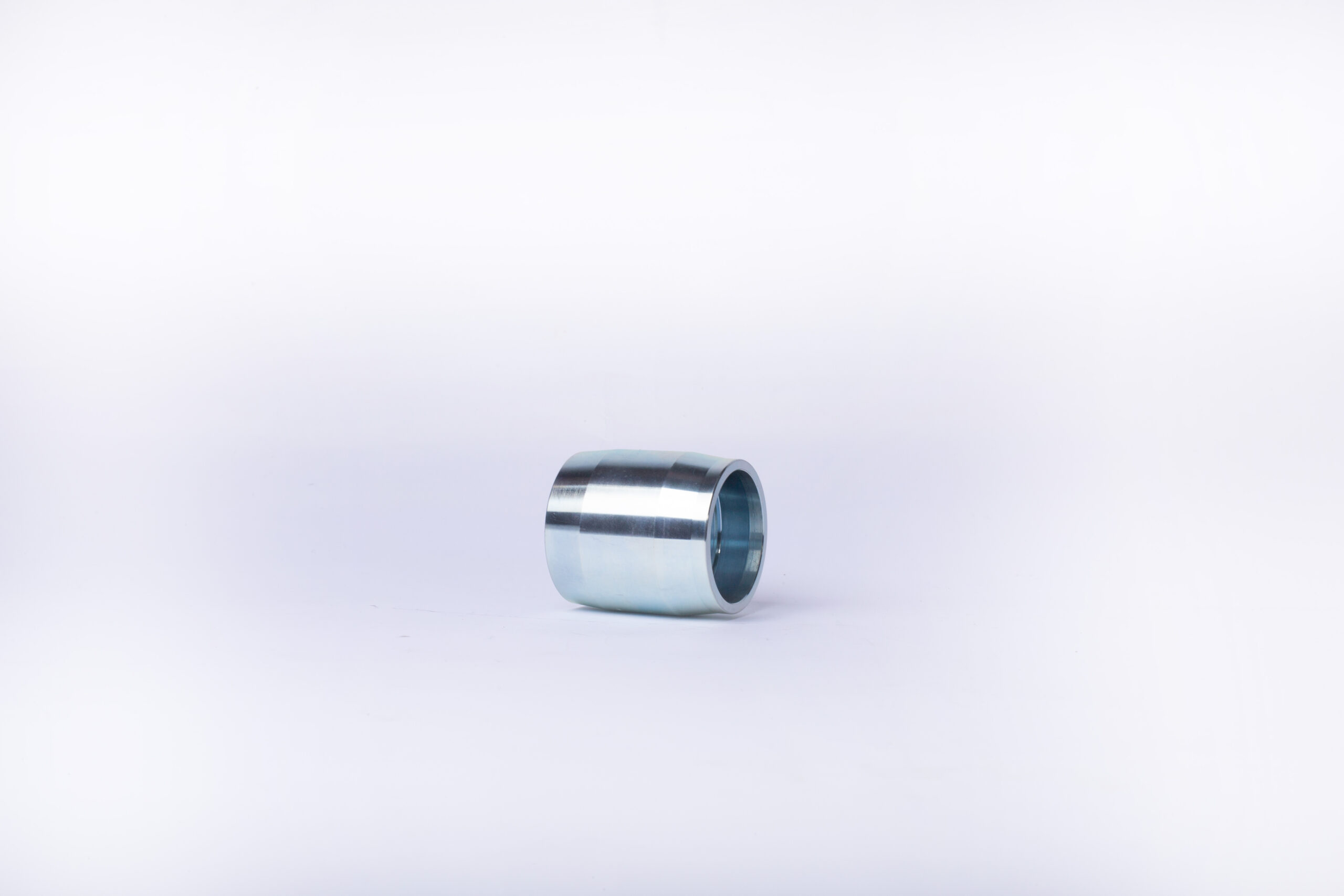

Product Name: Aluminum Forging

Product Type: Metal Forging

Material: Aluminum

Shape: Customized

Surface Treatment: Anodizing, Powder Coating, Spray Painting, Polishing

Production Process: Die Casting, Press Forging

Advantages:

1. High strength-to-weight ratio

2. Superior mechanical properties

3. Enhanced resistance to fatigue and wear

4. Tight dimensional tolerances

5. Cost-effective production

| Color | Silver |

|---|---|

| Material | Aluminum |

| MOQ | 1 Pcs |

| Sample | Available |

| Place of Origin | China |

Product Details

MINGYU Tech is a reputable supplier of the forge hammered aluminum for the telecommunications industry. With our advanced forging technology and expertise, we can produce forgings for a wide range of telecommunications equipment, including antennas, satellite dishes and support structures. Our team works closely with our customers to provide cost-effective solutions that meet their specific needs. We are committed to providing the highest quality products and excellent customer service to our customers in the telecommunications industry.

the forge hammered aluminum is a metal forming process that involves shaping the aluminum metal through the application of extreme pressure and heat. The process starts with a solid aluminum billet, which is heated to a high temperature and then is placed in a die. The die is a pre-designed tool with a specific shape and size, and it is used to shape the aluminum billet into the desired product. The application of pressure causes the metal to take the shape of the die, resulting in a forged aluminum product with enhanced strength and durability.

One of the main advantages of the forge hammered aluminum is its superior mechanical properties. The high-pressure and heat applied during the process ensure that the resulting product is more durable and stronger than other metal forming techniques. This makes it a preferred choice for industries such as aerospace, automotive, and military, where the products require high strength and resilience. Moreover, the forge hammered aluminum offers unlimited design possibilities. As the metal is heated and shaped, it can be easily molded into complex and intricate shapes, making it suitable for manufacturing a variety of products. This flexibility in design also translates into cost savings for manufacturers as it reduces the need for additional machining and finishing processes.

| Place of Origin | China |

| Material | Metal Aluminium Steel Copper Brass |

| Process | Forging+machining+HT+finish Machining |

| Surface treatment | Polishing |

| Application | Machinery Parts |

| Product name | the forge hammered aluminum |

| Certificate | TS16949/ISO9001 |

| Color | Customized Color |

| Quality Control | 100% Inspection |

| Lead Time | 18-36 Days |

| MOQ | 1 Piece |

| Supply Ability | 215925 Piece/Pieces per Month |

| Quantity (pieces) | > 523 |

| Lead time (days) | To be negotiated |

the forge hammered aluminum FAQs Guide.

Our company is dedicated to providing high-quality the forge hammered aluminum products to meet the needs of various industries. With advanced technology and skilled craftsmanship, we have become a leading manufacturer in the field of the forge hammered aluminum. Our products are widely used in aerospace, automotive, and construction industries, just to name a few. We take great pride in our products as they are not only durable and reliable, but also lightweight and eco-friendly. Through this introduction, we hope to showcase the versatility and excellence of our the forge hammered aluminum products. Thank you for choosing us as your trusted provider of top-notch the forge hammered aluminum products.

1.About the forge hammered aluminum customization services

Aluminum forging customization services are a great way to get the exact parts you need for your project. These services allow you to customize the shape, size, and design of your aluminum parts to meet your exact specifications. The process of aluminum forging involves heating the metal to a high temperature and then using a hammer or press to shape it into the desired shape. This process is often used to create parts with complex shapes and intricate details. Aluminum forging customization services can help you create parts that are strong, lightweight, and durable.

2.About the forge hammered aluminum quality system

Aluminum forging quality systems are designed to ensure that aluminum forgings meet the highest standards of quality and performance. Quality systems typically include a set of processes and procedures that are designed to ensure that all aluminum forgings meet the required specifications. Quality systems may include processes such as material selection, heat treatment, machining, and inspection. Quality systems also include documentation and record keeping to ensure that all processes are properly documented and tracked. Quality systems are essential for ensuring that aluminum forgings meet the highest standards of quality and performance.

3.How does heat treatment affect the strength and durability of the forge hammered aluminums?

We maintain a certain amount of R&D investment every year and continuously improve operational efficiency to provide better services to our cooperative customers.

Heat treatment can significantly improve the strength and durability of aluminum forgings. Heat treatment can increase the strength of aluminum by increasing the hardness of the material, which can help to reduce wear and tear. Heat treatment can also improve the fatigue strength of aluminum, which can help to increase the life of the part. Heat treatment can also improve the corrosion resistance of aluminum, which can help to increase the durability of the part.

4.Are there any differences in the mechanical properties of forged and cast aluminum?

We pay attention to the transformation of intellectual property protection and innovation achievements. Your OEM or ODM order design we have a complete confidentiality system.

Yes, there are differences in the mechanical properties of forged and cast aluminum. Forged aluminum is typically stronger and more ductile than cast aluminum, due to the forging process which increases the grain size and improves the mechanical properties. Forged aluminum also has a higher yield strength and tensile strength than cast aluminum. Cast aluminum is typically softer and more brittle than forged aluminum, and has a lower yield strength and tensile strength.

5.What are the steps involved in the the forge hammered aluminum process?

We continue to improve the forge hammered aluminum products and processes to improve efficiency.

1. Design: The first step in the aluminum forging process is to design the part. This includes determining the size, shape, and other specifications of the part.

2. Heating: The aluminum is heated to a temperature of around 800-900°C (1472-1652°F). This is done to make the aluminum malleable and easier to shape.

3. Forging: The heated aluminum is then placed in a die and forged into the desired shape. This is done using a hammer or press.

4. Finishing: The forged part is then finished by machining, grinding, or polishing. This is done to achieve the desired surface finish.

5. Inspection: The part is then inspected to ensure it meets the design specifications.

6. Heat Treatment: The part may then be heat treated to improve its strength and durability.

7. Final Inspection: The part is then inspected one final time before it is ready for use.

6.About the forge hammered aluminum production management system

The Aluminum Forging Production Management System is a comprehensive software solution designed to help aluminum forging companies manage their production processes. It provides a comprehensive set of tools to help manage the entire production process from order entry to delivery. The system includes features such as order tracking, inventory management, scheduling, quality control, and cost analysis. It also provides reporting and analytics to help companies make informed decisions about their production processes. The system is designed to be user-friendly and can be customized to meet the specific needs of each company.

7.Are there any surface treatment options for the forge hammered aluminums?

Our the forge hammered aluminum products undergo strict quality control to ensure customer satisfaction.

Yes, there are several surface treatment options for aluminum forgings, including anodizing, powder coating, painting, and plating. Anodizing is a process that creates a protective oxide layer on the surface of the aluminum, while powder coating and painting are used to add color and texture to the surface. Plating is used to add a layer of metal to the surface of the aluminum, such as chrome or nickel.

8.How does the choice of die affect the final product in the forge hammered aluminum?

We have established a good reputation and reliable partnerships within the the forge hammered aluminum industry.

The choice of die affects the final product in aluminum forging in several ways. The die design determines the shape of the final product, as well as the surface finish and dimensional accuracy. The die material also affects the final product, as different materials have different properties that can affect the strength and durability of the final product. Additionally, the die size and shape can affect the amount of force required to form the aluminum, as well as the amount of time it takes to complete the forging process.

9.Can the forge hammered aluminums be heat treated?

We have rich industry experience and professional knowledge, and have strong competitiveness in the market.

Yes, aluminum forgings can be heat treated. Heat treating is a process used to alter the physical and chemical properties of a material. It is commonly used to increase the strength and hardness of aluminum forgings.

10.About the forge hammered aluminum R&D capabilities

Aluminum forging R&D capabilities are highly advanced and have been developed over many years. Companies that specialize in aluminum forging have invested heavily in research and development to create new and improved processes and products. This has enabled them to produce high-quality aluminum components that are lighter, stronger, and more cost-effective than ever before. Aluminum forging R&D capabilities include the development of new alloys, improved forging techniques, and the use of advanced computer-aided design and manufacturing (CAD/CAM) systems. These capabilities have enabled aluminum forging companies to produce components that meet the highest standards of quality and performance.

11.Can the forge hammered aluminums be coated or plated?

We should have a stable supply chain and logistics capabilities, and provide customers with high -quality, low -priced the forge hammered aluminum products.

Yes, aluminum forgings can be coated or plated. Common coatings and platings for aluminum forgings include anodizing, powder coating, and electroplating.

12.Are there any surface finishing options for the forge hammered aluminums?

We should perform well in market competition, and the prices of the forge hammered aluminum products have a great competitive advantage.

Yes, there are several surface finishing options for aluminum forgings, including anodizing, powder coating, painting, and polishing.

13.About the forge hammered aluminum MOQ

The minimum order quantity (MOQ) for aluminum forging depends on the size and complexity of the part being forged. Generally, the MOQ for aluminum forging is between 500 and 1000 pieces. However, some aluminum forging companies may be willing to accept orders for smaller quantities.

Tag:large aluminum forged rings,aluminum forging temp measure,aluminum forged rings

Product Inquiry

We will respond within 12 hours, please pay attention to the email “@163.com” or “@alumforge.com”.

Also, you can go to the Contact Page, which provides a more detailed form, if you have more inquiries for products or would like to obtain OEM service.

Our sales experts will respond within 24 hours, please pay attention to the email with the suffix “@163.com”.