Product Name: Aluminum Forging

Product Type: Metal Forging

Material: Aluminum

Shape: Customized

Surface Treatment: Anodizing, Powder Coating, Spray Painting, Polishing

Production Process: Die Casting, Press Forging

Advantages:

1. High strength-to-weight ratio

2. Superior mechanical properties

3. Enhanced resistance to fatigue and wear

4. Tight dimensional tolerances

5. Cost-effective production

| Color | Silver |

|---|---|

| Material | Aluminum |

| MOQ | 1 Pcs |

| Sample | Available |

| Place of Origin | China |

Product Details

MINGYU Tech is a specialist in the production of large complex aluminum forged work non-stick coating for the oil and gas industry. We have the expertise and advanced equipment to manufacture forgings that can withstand harsh environments and extreme conditions. Our experienced team works closely with customers to provide customized solutions that meet their specific needs. We also provide testing and inspection services to ensure the quality and integrity of forgings. Customer satisfaction and product excellence are at the core of our business.

aluminum forged work non-stick coating is a manufacturing process that involves shaping aluminum alloys into customized parts and components through the application of compressive force. The process involves heating the aluminum to a specific temperature and then using extreme pressure to force it into a specific mold or die. This results in a uniform and strong end product that is highly durable and resistant to wear and tear.

At MINGYU Tech, we specialize in aluminum forged work non-stick coating and have years of experience in producing high-quality parts and components for various industries. Our state-of-the-art equipment and skilled technicians allow us to provide our clients with top-notch products that meet their exact specifications.

| Place of Origin | China |

| Material | Metal Aluminium Steel Copper Brass |

| Process | Forging+machining+HT+finish Machining |

| Surface treatment | Polishing |

| Application | Machinery Parts |

| Product name | aluminum forged work non-stick coating |

| Certificate | TS16949/ISO9001 |

| Color | Customized Color |

| Quality Control | 100% Inspection |

| Lead Time | 15-40 Days |

| MOQ | 1 Piece |

| Supply Ability | 191308 Piece/Pieces per Month |

| Quantity (pieces) | > 538 |

| Lead time (days) | To be negotiated |

aluminum forged work non-stick coating FAQs Guide.

Our company is dedicated to providing high-quality aluminum forged work non-stick coating products to meet the needs of various industries. With advanced technology and skilled craftsmanship, we have become a leading manufacturer in the field of aluminum forged work non-stick coating. Our products are widely used in aerospace, automotive, and construction industries, just to name a few. We take great pride in our products as they are not only durable and reliable, but also lightweight and eco-friendly. Through this introduction, we hope to showcase the versatility and excellence of our aluminum forged work non-stick coating products. Thank you for choosing us as your trusted provider of top-notch aluminum forged work non-stick coating products.

1.How does the shape and geometry of a part affect the aluminum forged work non-stick coating process?

The shape and geometry of a part can have a significant impact on the aluminum forging process. The shape of the part will determine the type of die that is used, the amount of force that is required to form the part, and the amount of time it takes to complete the forging process. Additionally, the geometry of the part will determine the amount of material that is required to form the part, the amount of time it takes to complete the forging process, and the amount of force that is required to form the part.

2.Can aluminum forged work non-stick coatings be welded or brazed?

Being one of the top aluminum forged work non-stick coating manufacturers in China, We attach great importance to this detail.

Yes, aluminum forgings can be welded or brazed. However, it is important to note that aluminum is a difficult material to weld and requires special techniques and equipment. Brazing is often the preferred method for joining aluminum forgings, as it is less likely to cause warping or cracking.

3.How does the surface finish affect the performance of aluminum forged work non-stick coatings?

The surface finish of aluminum forgings can have a significant impact on the performance of the part. A smooth, uniform surface finish can reduce friction and wear, improve fatigue strength, and reduce the risk of corrosion. A rough surface finish can increase friction and wear, reduce fatigue strength, and increase the risk of corrosion.

4.What is aluminum forged work non-stick coating?

We focus on innovation and continuous improvement to maintain a competitive advantage.

Aluminum forging is a metalworking process in which heated aluminum is shaped into desired shapes and sizes by applying compressive forces. It is a process that is used to create complex shapes and parts from aluminum. The process involves heating the aluminum to a temperature that is just below its melting point and then using a hammer or press to shape it into the desired shape. Aluminum forging is used in a variety of industries, including aerospace, automotive, and medical.

5.Are there any environmental benefits of using aluminum forged work non-stick coating?

We pay attention to user experience and product quality, and provide the best product quality and lowest production cost for cooperative customers.

Yes, aluminum forging offers several environmental benefits. Aluminum is a lightweight, durable, and recyclable material, which means that it can be reused and repurposed multiple times. This reduces the amount of energy and resources needed to produce new aluminum products. Additionally, aluminum forging is a more efficient process than other metal forming techniques, which reduces energy consumption and emissions. Finally, aluminum is a non-toxic material, which means that it does not release any hazardous chemicals into the environment.

6.About the scale of aluminum forged work non-stick coating factory

The size of an aluminum forging factory depends on the type of products it produces and the size of the orders it receives. Some aluminum forging factories may be small, producing only a few parts at a time, while others may be large, producing thousands of parts per day. The size of the factory also depends on the type of equipment used, the number of employees, and the amount of space available.

7.Are there any surface treatment options for aluminum forged work non-stick coatings?

Our aluminum forged work non-stick coating products undergo strict quality control to ensure customer satisfaction.

Yes, there are several surface treatment options for aluminum forgings, including anodizing, powder coating, painting, and plating. Anodizing is a process that creates a protective oxide layer on the surface of the aluminum, while powder coating and painting are used to add color and texture to the surface. Plating is used to add a layer of metal to the surface of the aluminum, such as chrome or nickel.

8.What industries commonly use aluminum forged work non-stick coatings?

We attach importance to the innovation ability and team spirit of employees, have advanced R & D facilities and laboratories, and have a good quality management system.

Aluminum forgings are commonly used in the automotive, aerospace, defense, and marine industries. They are also used in the construction, medical, and sporting goods industries.

9.What types of products can be made through aluminum forged work non-stick coating?

We pay attention to the introduction and training of talents, scientifically regulate the management system, and focus on cultural construction and team cohesion.

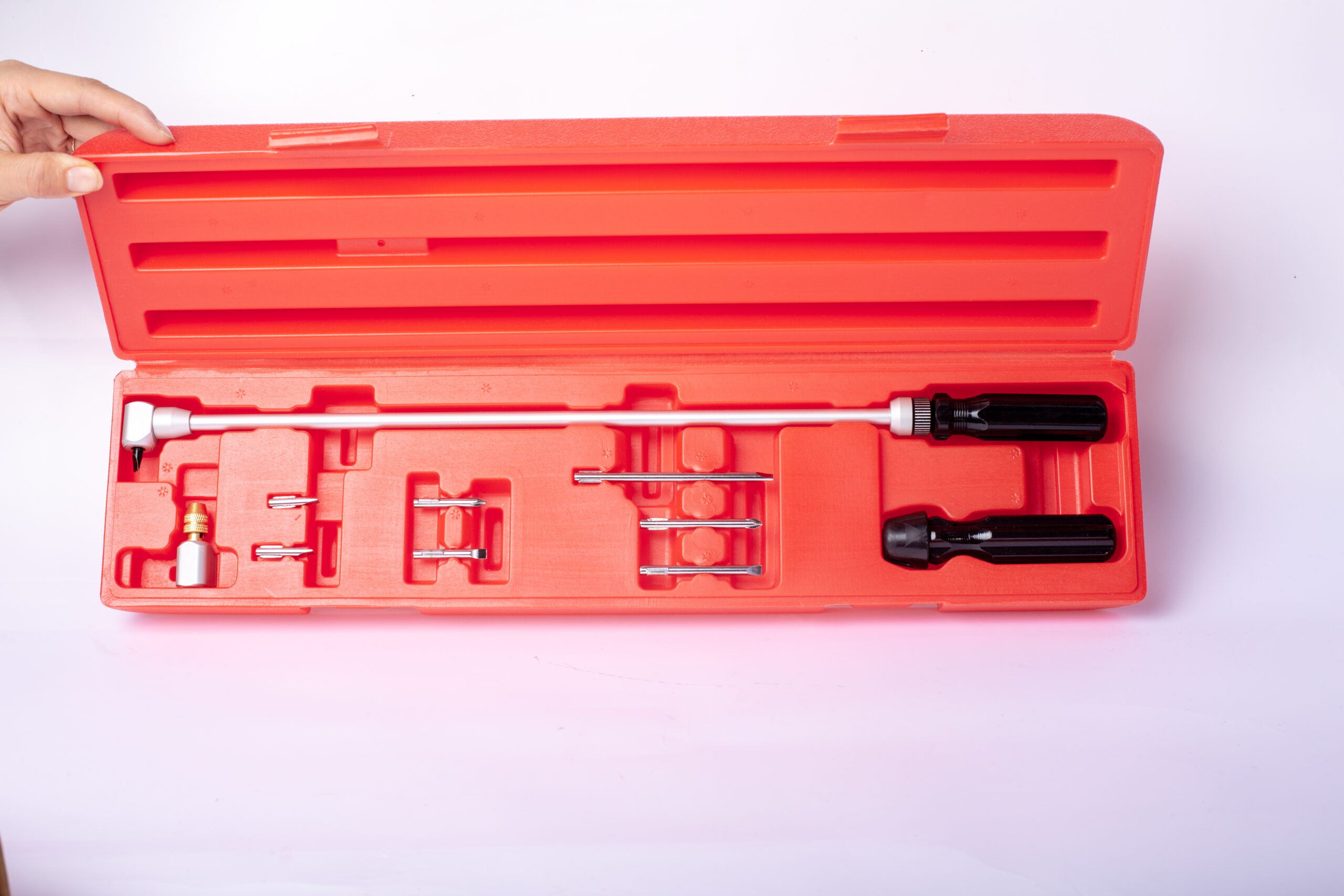

Aluminum forging can be used to create a wide variety of products, including automotive parts, aerospace components, hand tools, medical instruments, and industrial machinery. Aluminum forgings can also be used to create decorative items such as sculptures, jewelry, and architectural elements.

10.What are the properties of aluminum that make it suitable for forging?

We have the leading technology and innovation capabilities, and attach importance to employee training and development, and provide promotion opportunities.

1. Aluminum is lightweight and strong, making it ideal for forging.

2. Aluminum has a low melting point, making it easy to shape and form.

3. Aluminum is corrosion-resistant, making it suitable for outdoor applications.

4. Aluminum is malleable and ductile, making it easy to work with.

5. Aluminum is a good conductor of heat and electricity, making it suitable for electrical components.

6. Aluminum is non-magnetic, making it suitable for use in sensitive electronic equipment.

7. Aluminum is relatively inexpensive, making it a cost-effective choice for many applications.

11.Can aluminum be forged at room temperature?

We focus on our customers’ needs and strive to meet their expectations, so we take this very seriously.

No, aluminum cannot be forged at room temperature. It must be heated to a temperature of at least 700°F (371°C) before it can be forged.

12.What is the typical lead time for aluminum forged work non-stick coating production?

We have a professional team that is committed to the innovation and development of aluminum forged work non-stick coating.

The lead time for aluminum forging production can vary depending on the complexity of the part and the size of the order. Generally, lead times range from 4-8 weeks.

13.About aluminum forged work non-stick coating production equipment

Aluminum forging production equipment is used to shape and form aluminum into a variety of shapes and sizes. This equipment is used in a variety of industries, including automotive, aerospace, and construction. The equipment is used to create parts for cars, airplanes, and other products. It is also used to create custom parts for specific applications. The equipment is designed to be efficient and reliable, and it is capable of producing high-quality parts.

14.What are the key differences between open die and closed die aluminum forged work non-stick coating?

We continuously upgrade our skills and knowledge to adapt to changing aluminum forged work non-stick coating market needs.

Open die forging is a process in which a hammer or press is used to shape a piece of metal between two flat dies without completely enclosing it. This process is used to create large, custom-shaped parts. Closed die forging is a process in which a hammer or press is used to shape a piece of metal between two dies that completely enclose the metal. This process is used to create smaller, more precise parts with tighter tolerances.

Tag:forged aluminum bowl,forged aluminum wheel,general aluminum forge,hot forged vs cold forged aluminum

Product Inquiry

We will respond within 12 hours, please pay attention to the email “@163.com” or “@alumforge.com”.

Also, you can go to the Contact Page, which provides a more detailed form, if you have more inquiries for products or would like to obtain OEM service.

Our sales experts will respond within 24 hours, please pay attention to the email with the suffix “@163.com”.